Office of the Revisor of Statutes

Minnesota Administrative Rules

CHAPTER 7011, STANDARDS FOR STATIONARY SOURCES

MINNESOTA POLLUTION CONTROL AGENCY

| Part | Title |

|---|---|

| GENERALLY | |

| 7011.0010 | APPLICABILITY OF STANDARDS OF PERFORMANCE. |

| 7011.0020 | CIRCUMVENTION. |

| 7011.0050 | GENERAL PROVISIONS OF FEDERAL NEW SOURCE PERFORMANCE STANDARDS INCORPORATED BY REFERENCE. |

| CONTROL EQUIPMENT | |

| 7011.0060 | DEFINITIONS. |

| 7011.0061 | INCORPORATION BY REFERENCE. |

| 7011.0065 | APPLICABILITY. |

| 7011.0070 | LISTED CONTROL EQUIPMENT AND CONTROL EQUIPMENT EFFICIENCIES. |

| 7011.0072 | REQUIREMENTS FOR CERTIFIED HOODS. |

| 7011.0075 | LISTED CONTROL EQUIPMENT GENERAL REQUIREMENTS. |

| 7011.0080 | MONITORING AND RECORD KEEPING FOR LISTED CONTROL EQUIPMENT. |

| EMISSION STANDARDS FOR VISIBLE AIR CONTAMINANTS | |

| 7011.0100 | SCOPE. |

| 7011.0105 | VISIBLE EMISSION RESTRICTIONS FOR EXISTING FACILITIES. |

| 7011.0110 | VISIBLE EMISSION RESTRICTIONS FOR NEW FACILITIES. |

| 7011.0115 | PERFORMANCE TESTS. |

| 7011.0120 | OPACITY STANDARD ADJUSTMENT. |

| CONTROL OF FUGITIVE PARTICULATE MATTER | |

| 7011.0150 | PREVENTING PARTICULATE MATTER FROM BECOMING AIRBORNE. |

| 7011.0300 | [Repealed, 21 SR 693] |

| 7011.0305 | [Repealed, 21 SR 693] |

| 7011.0310 | [Repealed, 21 SR 693] |

| 7011.0315 | [Repealed, 21 SR 693] |

| 7011.0320 | [Repealed, 21 SR 693] |

| 7011.0325 | [Repealed, 21 SR 693] |

| 7011.0330 | [Repealed, 21 SR 693] |

| 7011.0400 | [Repealed, 22 SR 1237] |

| 7011.0405 | [Repealed, 22 SR 1237] |

| 7011.0410 | [Repealed, 22 SR 1237] |

| INDIRECT HEATING FOSSIL-FUEL-BURNING EQUIPMENT | |

| 7011.0500 | DEFINITIONS. |

| 7011.0505 | DETERMINATION OF APPLICABLE STANDARDS OF PERFORMANCE. |

| 7011.0510 | STANDARDS OF PERFORMANCE FOR EXISTING INDIRECT HEATING EQUIPMENT. |

| 7011.0515 | STANDARDS OF PERFORMANCE FOR NEW INDIRECT HEATING EQUIPMENT. |

| 7011.0520 | ALLOWANCE FOR STACK HEIGHT FOR INDIRECT HEATING EQUIPMENT. |

| 7011.0525 | HIGH HEATING VALUE. |

| 7011.0530 | PERFORMANCE TEST METHODS. |

| 7011.0535 | PERFORMANCE TEST PROCEDURES. |

| 7011.0540 | DERATE. |

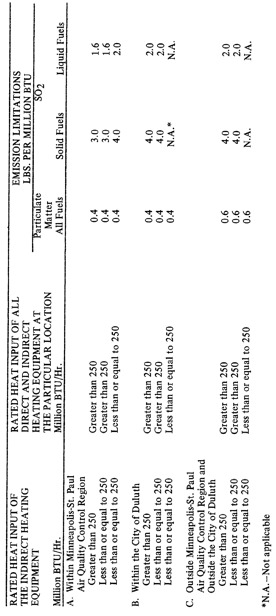

| 7011.0545 | TABLE I: EXISTING INDIRECT HEATING EQUIPMENT. |

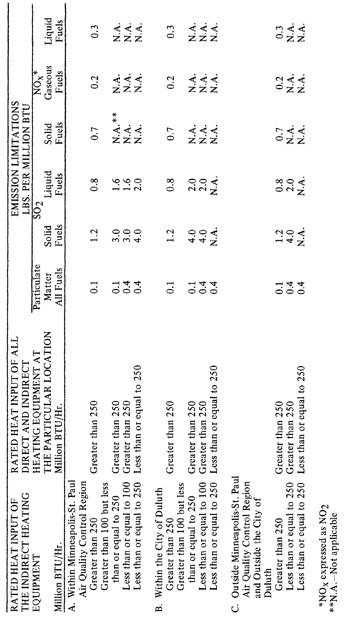

| 7011.0550 | TABLE II: NEW INDIRECT HEATING EQUIPMENT. |

| 7011.0551 | RECORD KEEPING AND REPORTING FOR INDIRECT HEATING UNITS COMBUSTING SOLID WASTE. |

| 7011.0553 | NITROGEN OXIDES EMISSION REDUCTION REQUIREMENTS FOR AFFECTED SOURCES. |

| FOSSIL-FUEL-FIRED STEAM GENERATORS | |

| 7011.0555 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| ELECTRIC UTILITY STEAM GENERATING UNITS | |

| 7011.0560 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| INDUSTRIAL-COMMERCIAL-INSTITUTIONAL STEAM GENERATING UNITS | |

| 7011.0565 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| SMALL INDUSTRIAL-COMMERCIAL-INSTITUTIONAL STEAM GENERATING UNITS |

|

| 7011.0570 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| DIRECT HEATING FOSSIL-FUEL-BURNING EQUIPMENT | |

| 7011.0600 | DEFINITIONS. |

| 7011.0605 | DETERMINATION OF APPLICABLE STANDARDS OF PERFORMANCE. |

| 7011.0610 | STANDARDS OF PERFORMANCE FOR FOSSIL-FUEL-BURNING DIRECT HEATING EQUIPMENT. |

| 7011.0615 | PERFORMANCE TEST METHODS. |

| 7011.0620 | PERFORMANCE TEST PROCEDURES. |

| 7011.0625 | RECORD KEEPING AND REPORTING FOR DIRECT HEATING UNITS COMBUSTING SOLID WASTE. |

| INDUSTRIAL PROCESS EQUIPMENT | |

| 7011.0700 | DEFINITIONS. |

| 7011.0705 | SCOPE. |

| 7011.0710 | STANDARDS OF PERFORMANCE FOR PRE-1969 INDUSTRIAL PROCESS EQUIPMENT. |

| 7011.0715 | STANDARDS OF PERFORMANCE FOR POST-1969 INDUSTRIAL PROCESS EQUIPMENT. |

| 7011.0720 | PERFORMANCE TEST METHODS. |

| 7011.0725 | PERFORMANCE TEST PROCEDURES. |

| 7011.0730 | TABLE 1. |

| 7011.0735 | TABLE 2. |

| 7011.0800 | [Repealed, 23 SR 2224] |

| 7011.0805 | [Repealed, 23 SR 2224] |

| 7011.0810 | [Repealed, 18 SR 580] |

| 7011.0815 | [Repealed, 23 SR 2224] |

| 7011.0820 | [Repealed, 23 SR 2224] |

| 7011.0825 | [Repealed, 23 SR 2224] |

| PORTLAND CEMENT PLANTS | |

| 7011.0830 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| CONCRETE MANUFACTURING PLANT STANDARDS OF PERFORMANCE | |

| 7011.0850 | DEFINITIONS. |

| 7011.0852 | STANDARDS OF PERFORMANCE FOR CONCRETE MANUFACTURING PLANTS. |

| 7011.0854 | CONCRETE MANUFACTURING PLANT CONTROL EQUIPMENT REQUIREMENTS. |

| 7011.0857 | PREVENTING PARTICULATE MATTER FROM BECOMING AIRBORNE. |

| 7011.0858 | NOISE. |

| 7011.0859 | SHUTDOWN AND BREAKDOWN PROCEDURES. |

| 7011.0860 | [Repealed, 27 SR 1579] |

| 7011.0865 | INCORPORATIONS BY REFERENCE. |

| 7011.0870 | STAGE-ONE VAPOR RECOVERY. |

| HOT MIX ASPHALT PLANTS | |

| 7011.0900 | DEFINITIONS. |

| 7011.0903 | COMPLIANCE WITH AMBIENT AIR QUALITY STANDARDS. |

| 7011.0905 | STANDARDS OF PERFORMANCE FOR EXISTING HOT MIX ASPHALT PLANTS. |

| 7011.0909 | STANDARDS OF PERFORMANCE FOR NEW HOT MIX ASPHALT PLANTS. |

| 7011.0910 | [Repealed, 18 SR 580] |

| 7011.0911 | MAINTENANCE OF DRYER BURNER. |

| 7011.0913 | HOT MIX ASPHALT PLANT MATERIALS, FUELS, AND ADDITIVES OPERATING REQUIREMENTS. |

| 7011.0915 | [Repealed, 20 SR 2253(NO. 42)] |

| 7011.0917 | ASPHALT PLANT CONTROL EQUIPMENT REQUIREMENTS. |

| 7011.0920 | PERFORMANCE TESTS. |

| 7011.0922 | OPERATIONAL REQUIREMENTS AND LIMITATIONS FROM PERFORMANCE TESTS. |

| 7011.0925 | [Renumbered 7011.0909] |

| ASPHALT PROCESSING AND ASPHALT ROOFING MANUFACTURE | |

| 7011.0950 | STANDARDS OF PERFORMANCE FOR NEW ASPHALT PROCESSING AND ASPHALT ROOFING MANUFACTURE. |

| BULK AGRICULTURAL COMMODITY FACILITIES | |

| 7011.1000 | DEFINITIONS. |

| 7011.1005 | STANDARDS OF PERFORMANCE FOR DRY BULK AGRICULTURAL COMMODITY FACILITIES. |

| 7011.1010 | NUISANCE. |

| 7011.1015 | CONTROL REQUIREMENTS SCHEDULE. |

| COAL HANDLING FACILITIES | |

| 7011.1100 | DEFINITIONS. |

| 7011.1105 | STANDARDS OF PERFORMANCE FOR CERTAIN COAL HANDLING FACILITIES. |

| 7011.1110 | STANDARDS OF PERFORMANCE FOR EXISTING OUTSTATE COAL HANDLING FACILITIES. |

| 7011.1115 | STANDARDS OF PERFORMANCE FOR PNEUMATIC COAL-CLEANING EQUIPMENT AND THERMAL DRYERS AT ANY COAL HANDLING FACILITY. |

| 7011.1120 | EXEMPTION. |

| 7011.1125 | CESSATION OF OPERATIONS. |

| 7011.1130 | PERFORMANCE TEST METHOD. |

| 7011.1135 | PERFORMANCE TEST PROCEDURES. |

| 7011.1140 | DUST SUPPRESSANT AGENTS. |

| COAL PREPARATION PLANTS | |

| 7011.1150 | STANDARDS OF PERFORMANCE FOR NEW COAL PREPARATION PLANTS. |

| WASTE COMBUSTORS | |

| 7011.1201 | DEFINITIONS. |

| 7011.1202 | [Repealed, 18 SR 2584] |

| 7011.1203 | [Repealed, 18 SR 2584] |

| 7011.1204 | [Repealed, 18 SR 2584] |

| 7011.1205 | INCORPORATIONS BY REFERENCE. |

| 7011.1206 | [Repealed, 18 SR 2584] |

| 7011.1207 | [Repealed, 18 SR 2584] |

| 7011.1210 | NOTIFICATION REQUIRED OF CLASS IV WASTE COMBUSTORS. |

| 7011.1215 | APPLICABILITY OF STANDARDS OF PERFORMANCE FOR WASTE COMBUSTORS. |

| 7011.1220 | PROHIBITIONS. |

| 7011.1225 | STANDARDS OF PERFORMANCE FOR WASTE COMBUSTORS. |

| 7011.1227 | TABLE 1. |

| 7011.1228 | NITROGEN OXIDES LIMITS FOR CLASS A WASTE COMBUSTORS. |

| 7011.1229 | TABLE 2. |

| 7011.1230 | STANDARDS OF PERFORMANCE FOR CLASS I MUNICIPAL WASTE COMBUSTORS. |

| 7011.1231 | TABLE 3. |

| 7011.1233 | TABLE 4. |

| 7011.1235 | REQUIREMENTS OF CLASS IV WASTE COMBUSTORS. |

| 7011.1240 | OPERATING REQUIREMENTS. |

| 7011.1245 | GENERAL WASTE COMBUSTOR FACILITY REQUIREMENTS. |

| 7011.1250 | INDUSTRIAL SOLID WASTE MANAGEMENT PLAN. |

| 7011.1255 | PLAN TO SEPARATE SOLID WASTES WHICH CONTAIN MERCURY. |

| 7011.1260 | CONTINUOUS MONITORING. |

| 7011.1265 | REQUIRED PERFORMANCE TESTS, METHODS, AND PROCEDURES. |

| 7011.1270 | PERFORMANCE TEST, WASTE COMPOSITION STUDY, AND ASH SAMPLING FREQUENCY. |

| 7011.1272 | MERCURY OR PCDD/PCDF ADDITIVE EQUIPMENT OPERATION, MONITORING, AND REPORTING. |

| 7011.1275 | PERSONNEL TRAINING. |

| 7011.1280 | OPERATOR CERTIFICATION. |

| 7011.1281 | FULL OPERATOR CERTIFICATION. |

| 7011.1282 | CERTIFIED MUNICIPAL WASTE COMBUSTOR EXAMINER CERTIFICATE. |

| 7011.1283 | DUTIES OF A CERTIFIED MUNICIPAL WASTE COMBUSTOR EXAMINER. |

| 7011.1284 | FULLY CERTIFIED OPERATOR. |

| 7011.1285 | OPERATING RECORDS AND REPORTS. |

| 7011.1290 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| INCINERATORS | |

| 7011.1299 | STANDARDS OF PERFORMANCE FOR INCINERATORS. |

| 7011.1300 | DEFINITIONS. |

| 7011.1305 | STANDARDS OF PERFORMANCE FOR EXISTING SEWAGE SLUDGE INCINERATORS. |

| 7011.1310 | STANDARDS OF PERFORMANCE FOR NEW SEWAGE SLUDGE INCINERATORS. |

| 7011.1315 | MONITORING OF OPERATIONS. |

| 7011.1320 | PERFORMANCE TEST METHODS. |

| 7011.1325 | PERFORMANCE TEST PROCEDURES. |

| 7011.1350 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| PETROLEUM REFINERIES | |

| 7011.1400 | DEFINITIONS. |

| 7011.1405 | STANDARDS OF PERFORMANCE FOR EXISTING AFFECTED FACILITIES AT PETROLEUM REFINERIES. |

| 7011.1410 | STANDARDS OF PERFORMANCE FOR NEW AFFECTED FACILITIES AT PETROLEUM REFINERIES. |

| 7011.1415 | EXEMPTIONS. |

| 7011.1420 | EMISSION MONITORING. |

| 7011.1425 | PERFORMANCE TEST METHODS. |

| 7011.1430 | PERFORMANCE TEST PROCEDURES. |

| 7011.1435 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| LIQUID PETROLEUM AND VOLATILE ORGANIC LIQUID STORAGE VESSELS |

|

| 7011.1500 | DEFINITIONS. |

| 7011.1505 | STANDARDS OF PERFORMANCE FOR STORAGE VESSELS. |

| 7011.1510 | MONITORING OF OPERATIONS. |

| 7011.1515 | EXCEPTION. |

| 7011.1520 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| BULK GASOLINE TERMINALS | |

| 7011.1550 | STANDARDS OF PERFORMANCE FOR NEW BULK GASOLINE TERMINALS. |

| SULFURIC ACID PLANTS | |

| 7011.1600 | DEFINITIONS. |

| 7011.1605 | STANDARDS OF PERFORMANCE OF EXISTING SULFURIC ACID PRODUCTION UNITS. |

| 7011.1610 | [Repealed, 18 SR 580] |

| 7011.1615 | CONTINUOUS EMISSION MONITORING. |

| 7011.1620 | PERFORMANCE TEST METHODS. |

| 7011.1625 | PERFORMANCE TEST PROCEDURES. |

| 7011.1630 | EXCEPTIONS. |

| 7011.1635 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| NITRIC ACID PLANTS | |

| 7011.1700 | DEFINITIONS. |

| 7011.1705 | STANDARDS OF PERFORMANCE FOR EXISTING NITRIC ACID PRODUCTION UNITS. |

| 7011.1710 | [Repealed, 18 SR 580] |

| 7011.1715 | EMISSION MONITORING. |

| 7011.1720 | PERFORMANCE TEST METHODS. |

| 7011.1725 | PERFORMANCE TEST PROCEDURES. |

| 7011.1730 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| 7011.1800 | [Repealed, 18 SR 580] |

| 7011.1805 | [Repealed, 18 SR 580] |

| 7011.1810 | [Repealed, 18 SR 580] |

| 7011.1815 | [Repealed, 18 SR 580] |

| LEAD SMELTERS | |

| 7011.1820 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| COPPER SMELTERS | |

| 7011.1840 | STANDARDS OF PERFORMANCE FOR NEW PRIMARY COPPER SMELTERS. |

| ZINC SMELTERS | |

| 7011.1880 | STANDARDS OF PERFORMANCE FOR NEW PRIMARY ZINC SMELTERS. |

| SECONDARY BRASS AND BRONZE INGOT PRODUCTION PLANTS | |

| 7011.1900 | DEFINITIONS. |

| 7011.1905 | STANDARDS OF PERFORMANCE FOR SECONDARY BRASS AND BRONZE INGOT PRODUCTION PLANTS. |

| 7011.1910 | PERFORMANCE TEST METHODS. |

| 7011.1915 | PERFORMANCE TEST PROCEDURES. |

| 7011.1920 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| IRON AND STEEL PLANTS | |

| 7011.2000 | DEFINITIONS. |

| 7011.2005 | STANDARDS OF PERFORMANCE FOR IRON AND STEEL PLANTS. |

| 7011.2010 | PERFORMANCE TEST METHODS. |

| 7011.2015 | PERFORMANCE TEST PROCEDURES. |

| 7011.2020 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| PRIMARY ALUMINUM REDUCTION PLANTS | |

| 7011.2050 | STANDARDS OF PERFORMANCE FOR NEW PRIMARY ALUMINUM REDUCTION PLANTS. |

| FERROALLOY PRODUCTION FACILITIES | |

| 7011.2080 | STANDARDS OF PERFORMANCE FOR NEW FERROALLOY PRODUCTION FACILITIES. |

| EMISSION STANDARDS FOR INORGANIC FIBROUS MATERIALS | |

| 7011.2100 | DEFINITIONS. |

| 7011.2105 | SPRAYING OF INORGANIC FIBROUS MATERIALS. |

| 7011.2200 | [Repealed, 22 SR 1237] |

| 7011.2205 | [Repealed, 22 SR 1237] |

| 7011.2210 | [Repealed, 22 SR 1237] |

| 7011.2215 | [Repealed, 21 SR 693] |

| 7011.2220 | Repealed by subpart |

| STATIONARY INTERNAL COMBUSTION ENGINES | |

| 7011.2300 | STANDARDS OF PERFORMANCE FOR STATIONARY INTERNAL COMBUSTION ENGINES. |

| 7011.2305 | STANDARDS OF PERFORMANCE FOR STATIONARY COMPRESSION IGNITION INTERNAL COMBUSTION ENGINES. |

| 7011.2310 | STANDARDS OF PERFORMANCE FOR STATIONARY SPARK IGNITION INTERNAL COMBUSTION ENGINES. |

| STATIONARY GAS TURBINES | |

| 7011.2350 | STANDARDS OF PERFORMANCE FOR NEW STATIONARY GAS TURBINES. |

| PHOSPHATE FERTILIZER INDUSTRY | |

| 7011.2400 | STANDARDS OF PERFORMANCE FOR PHOSPHATE FERTILIZER INDUSTRY. |

| KRAFT PULP MILLS | |

| 7011.2450 | STANDARDS OF PERFORMANCE FOR NEW KRAFT PULP MILLS. |

| GLASS MANUFACTURING PLANTS | |

| 7011.2500 | STANDARDS OF PERFORMANCE FOR NEW GLASS MANUFACTURING PLANTS. |

| SURFACE COATING | |

| 7011.2550 | STANDARDS OF PERFORMANCE FOR SURFACE COATING OF METAL FURNITURE. |

| 7011.2555 | STANDARDS OF PERFORMANCE FOR AUTOMOBILE AND LIGHT-DUTY TRUCK SURFACE COATING OPERATIONS. |

| 7011.2560 | STANDARDS OF PERFORMANCE FOR PRESSURE SENSITIVE TAPE AND LABEL SURFACE COATING OPERATIONS. |

| 7011.2565 | STANDARDS OF PERFORMANCE FOR INDUSTRIAL SURFACE COATING: LARGE APPLIANCES. |

| 7011.2570 | STANDARDS OF PERFORMANCE FOR METAL COIL SURFACE COATING. |

| 7011.2575 | STANDARDS OF PERFORMANCE FOR THE BEVERAGE CAN SURFACE COATING INDUSTRY. |

| 7011.2580 | STANDARDS OF PERFORMANCE FOR INDUSTRIAL SURFACE COATING: SURFACE COATING OF PLASTIC PARTS FOR BUSINESS MACHINES. |

| LIME MANUFACTURING PLANTS | |

| 7011.2600 | STANDARDS OF PERFORMANCE FOR NEW LIME MANUFACTURING PLANTS. |

| LEAD-ACID BATTERY MANUFACTURING PLANTS | |

| 7011.2650 | STANDARDS OF PERFORMANCE FOR NEW LEAD-ACID BATTERY MANUFACTURING PLANTS. |

| METALLIC MINERAL PROCESSING PLANTS | |

| 7011.2700 | STANDARDS OF PERFORMANCE FOR NEW METALLIC MINERAL PROCESSING PLANTS. |

| PHOSPHATE ROCK PLANTS | |

| 7011.2750 | STANDARDS OF PERFORMANCE FOR NEW PHOSPHATE ROCK PLANTS. |

| AMMONIUM SULFATE MANUFACTURE | |

| 7011.2800 | STANDARDS OF PERFORMANCE FOR AMMONIUM SULFATE MANUFACTURE. |

| GRAPHIC ARTS INDUSTRY | |

| 7011.2850 | STANDARDS OF PERFORMANCE FOR PUBLICATION ROTOGRAVURE PRINTING. |

| SYNTHETIC ORGANIC CHEMICALS MANUFACTURING INDUSTRY | |

| 7011.2900 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| NEW RESIDENTIAL WOOD HEATERS | |

| 7011.2950 | STANDARDS OF PERFORMANCE FOR NEW RESIDENTIAL WOOD HEATERS. |

| RUBBER TIRE MANUFACTURING INDUSTRY | |

| 7011.3000 | STANDARDS OF PERFORMANCE FOR THE RUBBER TIRE MANUFACTURING INDUSTRY. |

| POLYMER MANUFACTURING INDUSTRY | |

| 7011.3050 | STANDARDS OF PERFORMANCE FOR POLYMER MANUFACTURING INDUSTRY. |

| POLYMERIC COATING OF SUPPORTING SUBSTRATES FACILITIES | |

| 7011.3100 | STANDARDS OF PERFORMANCE FOR NEW POLYMERIC COATING OF SUPPORTING SUBSTRATES FACILITIES. |

| FLEXIBLE VINYL AND URETHANE COATING AND PRINTING | |

| 7011.3150 | STANDARDS OF PERFORMANCE FOR FLEXIBLE VINYL AND URETHANE COATING AND PRINTING. |

| SYNTHETIC FIBER PRODUCTION FACILITIES | |

| 7011.3200 | STANDARDS OF PERFORMANCE FOR NEW SYNTHETIC FIBER PRODUCTION FACILITIES. |

| PETROLEUM DRY CLEANERS | |

| 7011.3250 | STANDARDS OF PERFORMANCE FOR NEW PETROLEUM DRY CLEANERS. |

| ONSHORE NATURAL GAS PROCESSING PLANTS | |

| 7011.3300 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARDS BY REFERENCE. |

| NONMETALLIC MINERAL PROCESSING PLANTS | |

| 7011.3350 | STANDARDS OF PERFORMANCE FOR NEW NONMETALLIC MINERAL PROCESSING PLANTS. |

| WOOL FIBERGLASS INSULATION MANUFACTURING PLANTS | |

| 7011.3400 | STANDARDS OF PERFORMANCE FOR NEW WOOL FIBERGLASS INSULATION MANUFACTURING PLANTS. |

| VOC EMISSIONS FROM SOCMI REACTOR PROCESSES | |

| 7011.3430 | STANDARDS OF PERFORMANCE FOR VOC EMISSIONS FROM SOCMI REACTOR PROCESSES. |

| MAGNETIC TAPE COATING FACILITIES | |

| 7011.3450 | STANDARDS OF PERFORMANCE FOR NEW MAGNETIC TAPE COATING FACILITIES. |

| GAS EMISSIONS FROM MUNICIPAL SOLID WASTE LANDFILLS | |

| 7011.3500 | DEFINITIONS. |

| 7011.3505 | STANDARDS OF PERFORMANCE FOR EXISTING MUNICIPAL SOLID WASTE LANDFILLS. |

| 7011.3510 | INCORPORATION OF NEW SOURCE PERFORMANCE STANDARD BY REFERENCE. |

| 7011.3520 | [Repealed, 37 SR 991] |

| EMISSION STANDARDS FOR HAZARDOUS AIR POLLUTANTS | |

| 7011.7000 | GENERAL PROVISIONS OF FEDERAL NATIONAL EMISSION STANDARDS FOR HAZARDOUS AIR POLLUTANTS FOR SOURCE CATEGORIES INCORPORATED BY REFERENCE. |

| 7011.7030 | [Repealed, L 2012 c 272 s 98] |

| 7011.7040 | ORGANIC HAZARDOUS AIR POLLUTANTS FROM SYNTHETIC ORGANIC CHEMICAL MANUFACTURING INDUSTRY. |

| 7011.7060 | ORGANIC HAZARDOUS AIR POLLUTANTS FROM EQUIPMENT LEAKS. |

| 7011.7080 | COKE OVEN BATTERIES. |

| 7011.7090 | COKE OVENS: PUSHING, QUENCHING, AND BATTERY STACKS. |

| 7011.7100 | PERCHLOROETHYLENE DRY CLEANING FACILITIES. |

| 7011.7120 | CHROMIUM EMISSIONS FROM HARD AND DECORATIVE CHROMIUM ELECTROPLATING AND CHROMIUM ANODIZING TANKS. |

| 7011.7140 | ETHYLENE OXIDE EMISSIONS STANDARDS FOR STERILIZATION FACILITIES. |

| 7011.7160 | INDUSTRIAL PROCESS COOLING TOWERS. |

| 7011.7180 | GASOLINE DISTRIBUTION. |

| 7011.7200 | HALOGENATED SOLVENT CLEANING. |

| 7011.7220 | [Repealed, 28 SR 1482] |

| 7011.7235 | PRIMARY LEAD SMELTING. |

| 7011.7240 | SECONDARY LEAD SMELTING. |

| 7011.7260 | MARINE TANK VESSEL LOADING OPERATIONS. |

| 7011.7280 | PETROLEUM REFINERIES. |

| 7011.7290 | OIL AND NATURAL GAS PRODUCTION, TRANSMISSION, AND STORAGE. |

| 7011.7300 | MAGNETIC TAPE MANUFACTURING OPERATIONS. |

| 7011.7320 | AEROSPACE MANUFACTURING AND REWORK FACILITIES. |

| 7011.7340 | WOOD FURNITURE MANUFACTURING OPERATIONS. |

| 7011.7360 | SHIPBUILDING AND SHIP REPAIR OPERATIONS. |

| 7011.7370 | BOAT MANUFACTURING. |

| 7011.7380 | PRINTING AND PUBLISHING INDUSTRY. |

| 7011.7385 | PAPER AND OTHER WEB COATING. |

| 7011.7390 | MUNICIPAL SOLID WASTE LANDFILLS. |

| 7011.7400 | OFF-SITE WASTE OPERATIONS. |

| 7011.7410 | HAZARDOUS WASTE COMBUSTION. |

| 7011.7420 | POLYMERS AND RESINS. |

| 7011.7440 | [Repealed, 28 SR 1482] |

| 7011.7460 | FERROALLOYS PRODUCTION. |

| 7011.7480 | FLEXIBLE POLYURETHANE FOAM PRODUCTION. |

| 7011.7485 | FLEXIBLE POLYURETHANE FOAM FABRICATION OPERATIONS. |

| 7011.7520 | MINERAL WOOL PRODUCTION. |

| 7011.7560 | PESTICIDE ACTIVE INGREDIENT PRODUCTION. |

| 7011.7580 | PHARMACEUTICALS PRODUCTION. |

| 7011.7600 | PHOSPHORIC ACID MANUFACTURING AND PHOSPHATE FERTILIZERS PRODUCTION. |

| 7011.7610 | HYDROCHLORIC ACID PRODUCTION. |

| 7011.7620 | POLYETHER POLYOLS PRODUCTION. |

| 7011.7640 | PORTLAND CEMENT MANUFACTURING. |

| 7011.7650 | PRIMARY COPPER SMELTING. |

| 7011.7660 | PRIMARY ALUMINUM PRODUCTION. |

| 7011.7665 | SECONDARY ALUMINUM PRODUCTION. |

| 7011.7670 | STEEL PICKLING - HYDROCHLORIC ACID PROCESS. |

| 7011.7675 | INTEGRATED IRON AND STEEL MANUFACTURING FACILITIES. |

| 7011.7680 | PUBLICLY OWNED TREATMENT WORKS. |

| 7011.7700 | PULP AND PAPER PRODUCTION. |

| 7011.7720 | WET-FORMED FIBERGLASS MAT PRODUCTION. |

| 7011.7730 | WOOL FIBERGLASS MANUFACTURING. |

| 7011.7740 | CELLULOSE PRODUCTS MANUFACTURING. |

| 7011.7760 | LEATHER FINISHING OPERATIONS. |

| 7011.7770 | PRINTING, COATING, AND DYEING OF FABRICS AND OTHER TEXTILES. |

| 7011.7780 | MANUFACTURING NUTRITIONAL YEAST. |

| 7011.7800 | REINFORCED PLASTIC COMPOSITES PRODUCTION. |

| 7011.7820 | POLYVINYL CHLORIDE AND COPOLYMERS PRODUCTION. |

| 7011.7840 | SOLVENT EXTRACTION FOR VEGETABLE OIL PRODUCTION. |

| 7011.7860 | RUBBER TIRE MANUFACTURING. |

| 7011.7880 | FRICTION MATERIALS MANUFACTURING FACILITIES. |

| 7011.7900 | SURFACE COATING OF LARGE APPLIANCES. |

| 7011.7905 | SURFACE COATING OF METAL COIL. |

| 7011.7910 | SURFACE COATING OF METAL FURNITURE. |

| 7011.7920 | REFRACTORY PRODUCTS MANUFACTURING. |

| 7011.7930 | BRICK AND STRUCTURAL CLAY PRODUCTS MANUFACTURING. |

| 7011.7935 | CLAY CERAMICS MANUFACTURING. |

| 7011.7940 | ASPHALT PROCESSING AND ASPHALT ROOFING MANUFACTURING. |

| 7011.7960 | SEMICONDUCTOR MANUFACTURING. |

| 7011.7980 | ENGINE TEST CELLS/STANDS. |

| 7011.8000 | SURFACE COATING OF WOOD BUILDING PRODUCTS. |

| 7011.8010 | SITE REMEDIATION. |

| 7011.8020 | PRIMARY MAGNESIUM REFINING. |

| 7011.8030 | TACONITE IRON ORE PROCESSING. |

| 7011.8040 | IRON AND STEEL FOUNDRIES. |

| 7011.8050 | MISCELLANEOUS ORGANIC CHEMICAL MANUFACTURING. |

| 7011.8060 | SURFACE COATING OF METAL CANS. |

| 7011.8070 | MISCELLANEOUS COATING MANUFACTURING. |

| 7011.8080 | MERCURY EMISSIONS FROM MERCURY CELL CHLOR-ALKALI PLANTS. |

| 7011.8090 | SURFACE COATING OF MISCELLANEOUS METAL PARTS AND PRODUCTS. |

| 7011.8100 | LIME MANUFACTURING PLANTS. |

| 7011.8110 | ORGANIC LIQUIDS DISTRIBUTION (NONGASOLINE). |

| 7011.8120 | STATIONARY COMBUSTION TURBINES. |

| 7011.8130 | SURFACE COATING OF PLASTIC PARTS AND PRODUCTS. |

| 7011.8140 | SURFACE COATING OF AUTOMOBILES AND LIGHT-DUTY TRUCKS. |

| 7011.8150 | STATIONARY RECIPROCATING INTERNAL COMBUSTION ENGINES. |

| 7011.8160 | PLYWOOD AND COMPOSITE WOOD PRODUCTS. |

| 7011.8170 | INDUSTRIAL PROCESS COOLING TOWERS. |

| 7011.9900 | GENERAL PROVISIONS OF FEDERAL NATIONAL EMISSION STANDARDS FOR HAZARDOUS AIR POLLUTANTS INCORPORATED BY REFERENCE. |

| 7011.9910 | ARSENIC. |

| 7011.9920 | ASBESTOS. |

| 7011.9921 | DEFINITIONS. |

| 7011.9922 | MANUFACTURING OPERATIONS. |

| 7011.9923 | SPRAYING. |

| 7011.9924 | [Repealed, 18 SR 580] |

| 7011.9925 | FABRIC FILTER SPECIFICATIONS. |

| 7011.9926 | SUBSTITUTE DEVICES FOR FABRIC FILTERS. |

| 7011.9927 | INSTALLATION AND OPERATION OF CONTROL EQUIPMENT. |

| 7011.9930 | BENZENE. |

| 7011.9940 | BERYLLIUM. |

| 7011.9941 | [Repealed, 18 SR 580] |

| 7011.9942 | [Repealed, 18 SR 580] |

| 7011.9943 | [Repealed, 18 SR 580] |

| 7011.9944 | [Repealed, 18 SR 580] |

| 7011.9945 | [Repealed, 18 SR 580] |

| 7011.9950 | MERCURY. |

| 7011.9951 | [Repealed, 18 SR 580] |

| 7011.9952 | [Repealed, 18 SR 580] |

| 7011.9953 | [Repealed, 18 SR 580] |

| 7011.9954 | [Repealed, 18 SR 580] |

| 7011.9955 | [Repealed, 18 SR 580] |

| 7011.9960 | RADON. |

| 7011.9970 | RADIONUCLIDES. |

| 7011.9980 | VINYL CHLORIDE. |

| 7011.9990 | VOLATILE HAZARDOUS AIR POLLUTANTS. |

GENERALLY

7011.0010 APPLICABILITY OF STANDARDS OF PERFORMANCE.

Subpart 1.

Existing facility.

An owner or operator of an existing emission facility shall comply with all applicable state air pollution control rules for existing emission facilities.

Subp. 2.

New facility.

An owner or operator who constructs, modifies, or reconstructs an emission facility shall comply with the New Source Performance Standards, if applicable, and the standards of performance for a new emission facility set forth in the state air pollution control rules. However, if the administrator has determined a state standard of performance to be of equal or superior environmental protection compared to the New Source Performance Standards, then the owner or operator need only comply with the state standard of performance. "Administrator" has the meaning given in part 7007.0100, subpart 3.

Subp. 3.

Exception.

For the purpose of the state air pollution control rules, the use of an alternative type of fuel or raw material is not a modification if the existing facility was designed to accommodate the alternative type of fuel or raw material. An emission facility is considered to be designed to accommodate an alternative type of fuel or raw material if that use could be accomplished under the facility's construction specifications as amended prior to the change.

Subp. 4.

Opacity standards.

The opacity standards in an applicable requirement apply at all times except during periods of start-up, shutdown, and malfunction, and as otherwise provided in an applicable requirement or compliance document as defined in parts 7007.0100 and 7017.2005. The exemption for periods of start-up, shutdown, and malfunction applies only if:

A.

at all times, including periods of start-up, shutdown, or malfunction, the owner or operator, to the extent practicable, maintains and operates the affected emission facility and air pollution control equipment in a manner consistent with good operating practice for the installed equipment design. Determination of whether acceptable operating and maintenance procedures are being used shall be based on, among other information, monitoring results, opacity observations, review of operating and maintenance procedures, and inspection of the source;

B.

the owner or operator complies with parts 7019.1000 and 7019.2000 in the event of a shutdown, breakdown, or malfunction; and

C.

the applicable requirement or compliance document does not state that the opacity standard applies during such conditions.

Subp. 5.

Transition to new opacity averaging method.

All permits issued before July 27, 1998, are amended to reflect the amendments to this chapter adopted on July 27, 1998, that are related to opacity averaging and excursions.

Statutory Authority:

MS s 116.07

History:

8 SR 2275; 18 SR 614; 23 SR 145; 23 SR 2224

Published Electronically:

February 25, 2008

7011.0020 CIRCUMVENTION.

No owner or operator may install or use a device or means that conceals or dilutes emissions, which would otherwise violate a federal or state air pollution control rule, without reducing the total amount of pollutant emitted.

Statutory Authority:

MS s 116.07

History:

8 SR 2275; 18 SR 614

Published Electronically:

February 25, 2008

7011.0050 GENERAL PROVISIONS OF FEDERAL NEW SOURCE PERFORMANCE STANDARDS INCORPORATED BY REFERENCE.

For purposes of interpreting, applying, and enforcing New Source Performance Standards that are incorporated by reference into this chapter, Code of Federal Regulations, title 40, sections 60.1, 60.2, 60.3, 60.5, 60.6, 60.12, 60.14, 60.15, 60.17, and 60.18, as amended, are adopted and incorporated by reference.

All requests, reports, applications, submittals, and other communications to the administrator pursuant to New Source Performance Standards that are incorporated by reference into this chapter must be submitted to the commissioner.

Statutory Authority:

MS s 116.07

History:

18 SR 580

Published Electronically:

February 25, 2008

CONTROL EQUIPMENT

7011.0060 DEFINITIONS.

Subpart 1.

Scope.

The definitions in parts 7005.0100 and 7007.0100 apply to the terms used in parts 7011.0060 to 7011.0080 unless the terms are defined in this part. The definitions in this part apply to the terms used in parts 7011.0060 to 7011.0080.

Subp. 2.

Capture efficiency.

"Capture efficiency" means the percentage of emissions produced by a process that are captured by an enclosure and/or ductwork and transported to air pollution control equipment.

Subp. 3.

Collection efficiency.

"Collection efficiency" means the percentage of emissions entering the air pollution control equipment that are collected by the air pollution control equipment and thus removed from the exhaust stream. "Collection" pertains to pollutants that are collected but molecular composition may or may not be changed.

Subp. 3a.

Control efficiency.

"Control efficiency" has the meaning given to control equipment efficiency in subpart 3b.

Subp. 3b.

Control equipment efficiency.

"Control equipment efficiency" means the percentage of emissions produced by a process that are not emitted to the atmosphere. Control equipment efficiency is equal to the product of the capture efficiency and collection efficiency or the product of capture efficiency and destruction efficiency.

Subp. 3c.

Control equipment manufacturer.

"Control equipment manufacturer" means a person that manufactures and sells control equipment, if at least 50 percent of the dollar value of the annual control equipment sales are made to persons who are not a subsidiary, division, or subdivision of the control equipment manufacturer.

Subp. 3d.

Destruction efficiency.

"Destruction efficiency" means the percentage of emissions entering the air pollution control equipment that are destroyed by the air pollution control equipment and thus removed from the exhaust stream. "Destruction" pertains to pollutants that are destroyed whereby molecular composition is changed.

Subp. 3e.

Hood.

"Hood" means a shaped inlet to a pollution control system that does not totally surround emissions from an emissions unit, that is designed, used, and maintained to capture and discharge the air emissions through ductwork to control equipment, and that conforms to the design and operating practices recommended in "Industrial Ventilation - A Manual of Recommended Practice, American Conference of Governmental Industrial Hygienists." This document is subject to frequent change. A spray booth can be a hood if it meets the definition in this subpart.

Subp. 4.

Listed control equipment.

"Listed control equipment" means the control equipment at a stationary source listed in part 7011.0070, subpart 1a, Table A.

Subp. 4a.

Testing company.

"Testing company" means a corporation, partnership, limited liability company, or sole proprietorship that conducts evaluations of hood design parameters as a normal part of its business activities and that is not the owner or operator of the emission facility or a subsidiary, division, or subdivision of the owner or operator of the emission facility.

Subp. 5.

Total enclosure.

"Total enclosure" means an enclosure that completely surrounds emissions from an emissions unit such that all emissions are captured and discharged through ductwork to control equipment.

Statutory Authority:

MS s 116.07

History:

19 SR 1345; 22 SR 1237; 23 SR 2224; 32 SR 904

Published Electronically:

February 25, 2008

7011.0061 INCORPORATION BY REFERENCE.

For the purpose of parts 7011.0060 to 7011.0080, the document, Industrial Ventilation - A Manual of Recommended Practice, American Conference of Governmental Industrial Hygienists (1984), 1300 Kemper Meadow Drive, Cincinnati, Ohio 45240, is incorporated by reference. American Conference of Governmental Industrial Hygienists is the author and publisher. This document is available through the Minitex interlibrary loan system (University of Minnesota Library). This document is subject to frequent change.

Statutory Authority:

MS s 116.07

History:

19 SR 1345; 32 SR 904

Published Electronically:

February 25, 2008

7011.0065 APPLICABILITY.

Subpart 1.

Applicability.

The owner or operator of a stationary source shall comply with parts 7011.0060 to 7011.0080 if the owner or operator elected to use the control equipment efficiencies for listed control equipment established pursuant to part 7011.0070 to calculate potential to emit, from emissions units that discharge through the listed control equipment, to:

Statutory Authority:

MS s 116.07

History:

19 SR 1345; 22 SR 1237; 23 SR 2224; 29 SR 626; 32 SR 904

Published Electronically:

February 25, 2008

7011.0070 LISTED CONTROL EQUIPMENT AND CONTROL EQUIPMENT EFFICIENCIES.

Subpart 1.

Listed control equipment efficiencies.

A.

Unless a part 70, state, or general permit specifies a different control efficiency, the owner or operator of a stationary source must at all times attain at least the control efficiency listed in Table A for each piece of listed control equipment at the stationary source. The applicable control efficiency for a type of listed control equipment and a given pollutant is determined by whether air emissions are discharged to the control equipment through a hood that is certified as described in part 7011.0072, through a noncertified hood, or through a total enclosure. The control equipment efficiencies in Table A do not apply to any hazardous air pollutant.

Subp. 1a.

Exceptions where control efficiency disallowed.

The owner or operator may not use a control efficiency listed in Table A if:

A.

the commissioner determines that the listed efficiency is inapplicable or is not representative of the source due to complexity of the process or source of emissions, lack of reliable data, presence of a pollutant or constituent such as condensible particulate matter or an organic compound significantly more difficult to control than the overall VOC gas stream that makes the categorical efficiency nonrepresentative, or other site-specific conditions; or

B.

the commissioner determines that alternate site-specific requirements are necessary to ensure compliance with applicable requirements or to protect human health or the environment.

| CONTROL EQUIPMENT EFFICIENCY - TABLE A | |||||

| ID# | CONTROL EQUIPMENT DESCRIPTION | POLLUTANT | CONTROL EFFICIENCY | ||

| TOTAL ENCLO- SURE |

HOOD: CERTI- FIED |

HOOD: NOT CERTIFIED | |||

Table A - Section 1 - Equipment Designed Primarily for Particulate Matter Control

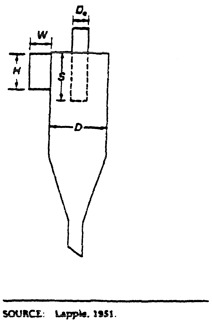

| PM CONTROL CATEGORY-CYCLONES means a device where airflow is forced to spin in a vortex through a tube | |||||

| 007 | Centrifugal Collector (cyclone)-high efficiency means: a cyclonic device with parameters stated in drawing 1 and table 1 | PM PM-10 |

90% 78% |

72% 62% |

54% 46% |

| 008 | Centrifugal Collector (cyclone)-medium efficiency means: a cyclonic device with parameters stated in drawing 1 and table 1 | PM PM-10 |

80% 60% |

64% 48% |

48% 36% |

| 009 | Centrifugal Collector (cyclone)-low efficiency means: a cyclonic device with parameters stated in drawing 1 and table 1 | PM PM-10 |

25% 25% |

20% 20% |

15% 15% |

| 076 | Multiple Cyclone without Fly Ash Reinjection means: a cyclonic device with more than one tube where fly ash is not reinjected | PM PM-10 |

90% 72% |

72% 58% |

54% 43% |

| 057, 085 |

Wet Cyclone Separator or Cyclonic Scrubbers means: a cyclonic device that sprays water into a cyclone | PM, PM-10 |

84% | 68% | 51% |

| 010, 011, 012, 128, 146 |

PM CONTROL CATEGORY- ELECTROSTATIC PRECIPITATORS means: a control device in which the incoming particulate matter receives an electrical charge and is then collected on a surface with the opposite electrical charge | ||||

| -assumed efficiency for boiler fly ash control | PM-10 | 40% | NA | NA | |

| -assumed efficiency for other applications | PM PM-10 |

98% 94% |

78% 75% |

59% 56% |

|

| PM CONTROL CATEGORY - OTHER CONTROLS | |||||

| 016, 017, 018 |

Fabric Filter means: a control device in which the incoming gas stream passes through a porous fabric filter forming a dust cake | PM PM-10 |

99% 93% |

79% 74% |

59% 56% |

| 052 | Spray Tower means: a control device in which the incoming gas stream passes through a chamber in which it contacts a liquid spray | PM PM-10 |

85% 84% |

68% 68% |

51% 51% |

| 053 | Venturi Scrubber means: a control device in which the incoming gas stream passes through a venturi into which a low pressure liquid is introduced | PM PM-10 |

94% 84% |

76% 68% |

57% 51% |

| 055 | Impingement Plate Scrubber means: a control device in which the incoming gas stream passes a liquid spray and is then directed at high velocity into a plate | PM PM-10 |

77% 77% |

62% 62% |

46% 46% |

| 056, 113 |

Mechanically Aided Separator means: a device that relies on inertia for separating particles from a gas stream | PM PM-10 |

64% 5% |

52% 4% |

39% 3% |

| 058 | Wall or Panel Filter means: a control device in which the exiting gas stream passes through a panel of coarse fibers. Other Wall Filters means removable panels for cleaning and replacement, or liquid curtains for particulate removal that provide little resistance to air flow | PM PM-10 |

85% 85% |

68% 68% |

51% 51% |

| 101 | HEPA Filter or ULPA Filter means: a high efficiency wall or panel filter designed for collection of submicron particles | PM PM-10 |

99.98% 99.98% |

80% 80% |

60% 60% |

| 503 | Charged Scrubber means: a control device in which electric power is used to precharge particulate matter in the gas stream as a means of increasing the scrubber's collection efficiency for fine particles | PM PM-10 |

94% 84% |

76% 68% |

57% 51% |

| 517 | Condensation Scrubber means: a control device in which steam is injected into a wet scrubber to create supersaturated conditions and promote condensation of water on fine particulate matter in the gas stream | PM PM-10 |

94% 84% |

76% 68% |

57% 51% |

Table A - Section 2 - Equipment Designed for VOC Control (includes efficiencies for pollutants where there is a co-benefit of control)

| VOC CONTROL CATEGORY | |||||

| 019, 020, 109, 116, 509 | Catalytic Afterburners (catalytic oxidation) means: a device used to reduce VOC's to the products of combustion through catalytic (use of a catalyst) oxidation in a combustion chamber | VOC PM PM-10 CO |

94% 62% 62% 94% |

76% 50% 50% 76% |

57% 37% 38% 57% |

| 021, 022, 131, 133, 510 | Thermal Afterburners (thermal oxidation) means: a device used to reduce VOC's to the products of combustion through thermal (high temperature) oxidation in a combustion chamber | VOC PM PM-10 CO |

97% 62% 62% 97% |

78% 50% 50% 78% |

58% 37% 37% 58% |

| 023 | Flaring or Direct Combustor means: a device in which air, combustible organic waste gases, and supplementary fuel (if needed) react in the flame zone (e.g., at the flare tip) to destroy the VOC's | VOC PM PM-10 CO |

98% 61% 61% 98% |

79% 50% 50% 79% |

59% 37% 37% 59% |

Drawing 1

| Table 1 | |||

| Cyclone Type | |||

| Ratio Dimensions | High Efficiency | Medium Efficiency | Low Efficiency |

| Height of inlet, H/D | ≤0.44 | >0.44 and <0.8 | ≥0.8 |

| Width of inlet, W/D | ≤0.2 | >0.2 and <0.375 | ≥0.375 |

| Diameter of gas exit, De/D | ≤0.4 | >0.4 and <0.75 | ≥0.75 |

| Length of vortex finder, S/D | ≤0.5 | >0.5 and <0.875 | ≥0.875 |

If one or more of the "ratio dimensions," as listed in table 1, are in a different efficiency category (high, medium, low), then the lowest efficiency category shall be applied.

Subp. 1b.

Transition period.

Any owner or operator of a stationary source that used the control efficiencies in part 7011.0070 to qualify for its permit and is ineligible for its permit on or after January 1, 2007, shall apply for another type of permit on or before December 31, 2008.

Subp. 2.

Alternative control equipment and capture efficiencies; control efficiencies for hazardous air pollutants.

The owner or operator of a stationary source may use an alternative control equipment efficiency or capture efficiency or both for the control equipment listed in subpart 1, if the actual control efficiency or capture efficiency has been verified by a performance test approved by the commissioner under parts 7017.2001 to 7017.2060. The owner or operator of a stationary source may use a control equipment efficiency for listed control equipment for a hazardous air pollutant, if the control efficiency has been verified by a performance test approved by the commissioner under parts 7017.2001 to 7017.2060. The request for the alternative control efficiency or capture efficiency or both may be made through a permit application for a part 70, state, registration, capped, or general permit, or in a required notice or application submitted under parts 7007.1150 to 7007.1500. The owner or operator of a stationary source must attain at all times the alternative control efficiency or capture efficiency or both for a piece of listed control equipment at the stationary source established under this subpart.

Statutory Authority:

MS s 116.07

History:

19 SR 1345; 20 SR 2316; 22 SR 1237; 23 SR 2224; 29 SR 626; 32 SR 904

Published Electronically:

February 25, 2008

7011.0072 REQUIREMENTS FOR CERTIFIED HOODS.

Subpart 1.

Applicability.

This part applies only to certified hoods and hoods the owner or operator elects to be certified. Nothing in this part shall be construed to allow the owner or operator of an emission facility to violate an applicable requirement or compliance document. Hoods evaluated before June 8, 1999, using a form, the contents of which differ from the content in subpart 3, are not required to be reevaluated, unless requested by the commissioner to demonstrate continued conformity with the design and operating practices described in the manual incorporated by reference under part 7011.0061.

Subp. 2.

Certification required.

In order to use a certified hood control efficiency value in part 7011.0070, subpart 1a, Table A, the owner or operator of a stationary source must:

B.

document, on a form provided by the commissioner, that the hood conforms to the design and operating practices recommended in the manual incorporated by reference under part 7011.0061 and must include with the permit application a certification statement as specified in item C, if the hood exists at the time of application. If the hood does not exist at the time of application, then the certification required in item C shall be sent to the commissioner within 30 days after start-up. The form used to demonstrate that the hood conforms to the required design and operating practices shall contain the elements listed in subpart 3; and

C.

include on the form required under item B a certification statement signed by the responsible official, stating as follows: "I certify under penalty of law that the aforementioned hood(s) has (have) been evaluated under my direction or supervision by qualified personnel and that, to the best of my knowledge and belief, the (each) hood conforms to the design and operating practices recommended in "Industrial Ventilation - A Manual of Recommended Practice, American Conference of Governmental Industrial Hygienists.""

Subp. 3.

Contents of hood evaluation form.

The hood evaluation form required in subpart 2 shall include:

B.

design capture velocity and justification for use of this velocity and a list of the manual pages relied on;

F.

actual values of design parameters listed in items A to D, as well as fan rotation speed or fan power draw, as determined through testing.

Subp. 4.

Monitoring and record keeping.

The owner or operator of a certified hood shall:

A.

maintain at the stationary source the most current record of each hood evaluation required by part 7011.0070; and

B.

measure the fan rotation speed, fan power draw, face velocity, or other comparable air flow indicator for each hood and maintain a yearly summary of these measurements. Each yearly summary shall be maintained at the stationary source for a minimum of five years.

Statutory Authority:

MS s 116.07

History:

32 SR 904

Published Electronically:

February 25, 2008

7011.0075 LISTED CONTROL EQUIPMENT GENERAL REQUIREMENTS.

Subpart 1.

Operation of control equipment.

The owner or operator of a stationary source shall operate all listed control equipment located at the stationary source whenever operating the emission units controlled by the listed control equipment in compliance with parts 7011.0060 to 7011.0080. Unless specifically allowed by a part 70, state, or general permit, each piece of listed control equipment, with the exception of low-temperature fabric filters (ID #018) using visible emissions as the monitoring parameter under part 7011.0080, shall at all times be operated in the range established by the control equipment manufacturer's specifications for each monitoring parameter listed in part 7011.0080, or within the operating parameters set by the commissioner as the result of the most recent performance test conducted to determine control efficiency under parts 7017.2001 to 7017.2060 if those are more restrictive.

The owner or operator with fabric filters (ID #016, #017, #018) using pressure drop as the monitoring parameter under part 7011.0080 and applying for a registration permit or a capped permit, may request an alternative range to the control equipment manufacturer's specifications, if the proposed range is based on two years of compliant monitoring data supplied with the request. The proposed operating range shall be deemed acceptable unless the owner or operator is notified otherwise in writing within 30 days of receipt by the commissioner. The commissioner shall deny a request for an alternative monitoring parameter range if the commissioner finds that:

A.

an owner or operator has failed to disclose fully all facts relevant to the proposed monitoring parameter range of the control device or the owner or operator has knowingly submitted false or misleading information to the commissioner;

B.

operation of the control device in the monitoring parameter range proposed by the owner or operator would result in noncompliance with applicable requirements, endanger human health or the environment, or subject the stationary source to different applicable requirements or requirements under chapter 7007; or

Subp. 2.

Maintenance of control equipment.

The owner or operator of a stationary source shall maintain each piece of listed control equipment according to the control equipment manufacturer's specifications, shall comply with source-specific maintenance requirements specified in a part 70, state, or general permit, and shall perform the following on each piece of listed control equipment:

A.

maintain an inventory of spare parts that are subject to frequent replacement, as required by the manufacturing specification or documented in records under items H and I;

B.

train staff on the operation and monitoring of control equipment and troubleshooting, and train and require staff to respond to indications of malfunctioning equipment, including alarms and other indicators of abnormal operation;

C.

thoroughly inspect all control equipment at least annually, or as required by the manufacturing specification (this often requires shutting down temporarily);

D.

inspect monthly, or as required by the manufacturing specification, components that are subject to wear or plugging, for example: bearings, belts, hoses, fans, nozzles, orifices, and ducts;

E.

inspect quarterly, or as required by the manufacturing specification, components that are not subject to wear including structural components, housings, ducts, and hoods;

F.

check daily, or as required by the manufacturing specification, monitoring equipment, for example: pressure gauges, chart recorders, temperature indicators, and recorders;

G.

calibrate annually, or as required by the manufacturing specification, all monitoring equipment;

H.

maintain a record of activities conducted in items A to G consisting of the activity completed, the date the activity was completed, and any corrective action taken; and

Subp. 3.

Installation of monitoring equipment.

The owner or operator of a stationary source shall install monitoring equipment to measure the operating parameters of all listed control equipment as specified by parts 7011.0072 and 7011.0080 or by source specific monitoring requirements specified in a part 70, state, or general permit. The monitoring equipment must be installed prior to operation of any new process equipment controlled by the control equipment or, for stationary sources in operation on December 27, 1994, by the application deadline listed in part 7007.0350, subpart 1, item A. The owner or operator of a stationary source shall operate the monitoring equipment for each piece of listed control equipment at all times the listed control equipment is required to operate in compliance with part 7011.0075.

Subp. 4.

Shutdown and breakdown procedures.

In the event of a shutdown of listed control equipment, or a breakdown of listed control equipment, the owner or operator of a stationary source shall comply with part 7019.1000.

Subp. 5.

Deviation of listed control equipment from operating specifications.

The owner or operator of a stationary source shall report to the commissioner in accordance with the deadlines in part 7007.0800, subpart 6, item A, subitem (2), any recorded reading outside the specification or range of specification allowed by subpart 1 of any monitored operating parameter required by part 7011.0080, except that owners or operators with a registration permit option D or a capped permit to which parts 7011.0060 to 7011.0080 apply shall make this report only if a deviation occurred in the reporting period. Owners or operators of low-temperature fabric control equipment (ID #018) using visible emissions as the monitoring parameter under part 7011.0080 shall report any visible emissions observed from the control equipment as a deviation.

Subp. 6.

Demonstration of capture and control equipment efficiency.

The owner or operator shall, upon request of the commissioner or the administrator, conduct a performance test under parts 7017.2001 to 7017.2060 to determine the capture efficiency of a hood or other capture device or to determine the efficiency of the control equipment. In addition to the reasons specified in part 7017.2020, subpart 1, the commissioner or the administrator may make such a request to verify that the capture device or control equipment at a stationary source is attaining the efficiency assumed under part 7011.0070.

Subp. 7.

Recalculation of potential to emit.

A.

The owner or operator shall recalculate the potential to emit of the stationary source under part 7007.0150, subpart 4, or under part 7007.1200 for amendments to part 70 or state permits, if the owner or operator becomes aware of any information indicating that the calculation originally performed under part 7007.0150, subpart 4, or 7007.1200, would change because the listed control equipment is not as efficient as originally assumed under part 7011.0070 or changes have been made to decrease the listed control equipment's efficiency. The owner or operator shall submit this recalculation to the commissioner within 30 days of becoming aware of the information.

B.

The owner or operator shall, upon request of the commissioner or the administrator, recalculate the potential to emit of the stationary source under part 7007.0150, subpart 4, or part 7007.1200 for amendments to part 70 and state permits, and submit the recalculation to the commissioner or the administrator by the date specified in the request.

Statutory Authority:

MS s 116.07

History:

19 SR 1345; 22 SR 1237; 23 SR 2224; 29 SR 626; 32 SR 904

Published Electronically:

February 25, 2008

7011.0080 MONITORING AND RECORD KEEPING FOR LISTED CONTROL EQUIPMENT.

The owner or operator of a stationary source shall comply with the monitoring and record keeping required for listed control equipment by the table in this part. The owner or operator shall maintain the records required by this part for a minimum of five years from the date the record was made. Unless a specific format is required, the records may be maintained in either electronic or paper format. For certified hoods, the owner or operator shall comply with part 7011.0072.

| Identification Number(s) | Pollution Control Equipment Type | Monitoring Parameter(s) | Record-keeping Requirement |

A.

Equipment designed for particulate matter control

| 007, 008, 009, 076, | Centrifugal collector (cyclone) | Pressure drop | Record pressure drop every 24 hours if in operation |

| 010, 011, 012, 128, 146 | Electrostatic precipitator | Voltage, secondary current, and, if used, conditioning agent flow rate | Continuous readout of voltage, and secondary current. If used, daily record of conditioning agent flow rate |

| 016, 017 | Fabric filter (bag house), high temperature (T>250°F), medium temperature (180°F> T<250°F) | Pressure drop | Record pressure drop every 24 hours if in operation |

| 018 | Fabric filter (bag house), low temperature (T<180°F) | Pressure drop or visible emissions observation from filter outlet during an entire cleaning cycle, unless the commissioner specifies pressure drop and/or visible emissions as the indicator(s) of fabric filter performance | Record pressure drop every 24 hours if in operation, or Record whether any visible emissions are observed and the time period of observation every 24 hours if in operation; or record both if the commissioner requires monitoring of both parameters |

| 052 | Spray tower | Liquid flow rate and pressure drop | Record each parameter every 24 hours if in operation |

| 053, 055 | Venturi scrubber, impingement plate scrubber | Pressure drop and liquid flow rate | Record each parameter every 24 hours if in operation |

| 056, 113 | Mechanically aided separator | Pressure drop | Record every 24 hours if in operation |

| 058, 101 | HEPA and other wall filters | Condition of the filters, including, but not limited to, alignment, saturation, and tears and holes | Record of filter(s) condition every 24 hours if in operation |

| 057, 085 | Wet cyclone separator | Pressure drop; and water pressure | Record each parameter every 24 hours if in operation |

| 503 | Charged scrubber | Pressure drop and liquid flow rate | Record each parameter every 24 hours if in operation |

| 517 | Condensation scrubber | Pressure drop and either steam supply rate or blowdown rate | Record each parameter every 24 hours if in operation |

B.

Equipment designed for volatile organic compound control

| 021, 022, 131, 133, 510 | Thermal afterburner | Combustion temperature or inlet and outlet temperatures | Record temperatures at least once every 15 minutes |

| 019, 020, 109, 116, 509 | Catalytic afterburner | Inlet and outlet temperatures; and catalyst bed reactivity as per manufacturer's specifications | Record temperatures or manual readings at least once every 15 minutes; and record results of catalyst bed reactivity |

| 023 | Flaring | Temperature indicating presence of a flame | Record temperatures at least once every 15 minutes |

Statutory Authority:

MS s 116.07

History:

19 SR 1345; 20 SR 2316; 23 SR 2224; 32 SR 904

Published Electronically:

February 25, 2008

EMISSION STANDARDS FOR VISIBLE AIR CONTAMINANTS

7011.0100 SCOPE.

The standards of performance in parts 7011.0100 to 7011.0115 apply to any emission facility for which a specific standard of performance has not been promulgated in another rule.

Statutory Authority:

MS s 116.07

History:

18 SR 614

Published Electronically:

February 25, 2008

7011.0105 VISIBLE EMISSION RESTRICTIONS FOR EXISTING FACILITIES.

No owner or operator of an existing emission facility to which parts 7011.0100 to 7011.0115 are applicable shall cause to be discharged into the atmosphere from the facility any gases which exhibit greater than 20 percent opacity; except for one six-minute period per hour of not more than 33 percent opacity. An exceedance of this opacity standard occurs whenever any one-hour period contains two or more six-minute periods during which the average opacity exceeds 20 percent or whenever any one-hour period contains one or more six-minute periods during which the average opacity exceeds 33 percent. For the purposes of this part, "existing emission facility" means an emission facility on which construction, modification, or reconstruction did not commence after January 31, 1977.

Statutory Authority:

MS s 116.07

History:

18 SR 614; 22 SR 1237; 23 SR 145

Published Electronically:

February 25, 2008

7011.0110 VISIBLE EMISSION RESTRICTIONS FOR NEW FACILITIES.

No owner or operator of a new emission facility to which parts 7011.0100 to 7011.0115 are applicable shall cause to be discharged into the atmosphere from the facility any gases which exhibit greater than 20 percent opacity. For the purposes of this part, "new emission facility" means an emission facility on which construction, modification, or reconstruction commenced after January 31, 1977.

Statutory Authority:

MS s 116.07

History:

18 SR 614; 22 SR 1237

Published Electronically:

February 25, 2008

7011.0115 PERFORMANCE TESTS.

Unless another method is approved by the agency, any person required to submit performance tests for emission facilities for which parts 7011.0100 to 7011.0115 are applicable shall utilize Method 9 for visual determination of opacity.

Performance tests shall be conducted according to the requirements of this part and parts 7017.2001 to 7017.2060.

Statutory Authority:

MS s 116.07

History:

18 SR 614; 18 SR 1412

Published Electronically:

February 25, 2008

7011.0120 OPACITY STANDARD ADJUSTMENT.

Subpart 1.

Application for permit modification.

An owner or operator of an emission facility may file an application for a permit modification under chapter 7007 for adjustment of the opacity standard applicable to an emissions unit. In addition to the items required under chapter 7007, the application must contain data that demonstrates that:

A.

based on tests conducted under parts 7017.1002 to 7017.2060, the emissions unit is in compliance with the applicable standard of performance for particulate matter and all other standards of performance, except the opacity standard;

B.

the stationary source is in compliance with all applicable standards of performance except the opacity standard at the emissions unit for which adjustments are being sought or have already been permitted by the agency; and

C.

the stationary source was operated in a manner to minimize the opacity of emissions at the emissions unit during the performance tests conducted under item A.

Subp. 2.

Atmospheric dispersion modeling.

If the data submitted under subpart 1 indicates that an adjustment of the opacity standard may cause or contribute to a violation of an ambient air quality standard, the agency shall require the owner or operator to conduct atmospheric dispersion modeling and include the results of the modeling in the application for a permit modification. However, a stationary source that has potential emissions of particulate matter of less than 25 tons per year is not required to conduct modeling. Modeling must be performed according to "Guidelines on Air Quality Models," EPA-450/2-78-027R, as amended by supplemental updates, or methods that the commissioner finds to be comparably reliable. The Guidelines are incorporated by reference. The Guidelines are written and published by the USEPA, Office of Air and Radiation, Office of Air Quality Planning and Standards, Research Triangle Park, North Carolina 27711. The guidelines are subject to frequent change and are available from the Minnesota State Law Library, 25 Rev. Dr. Martin Luther King Jr. Blvd., Saint Paul, Minnesota 55155.

Subp. 3.

Opacity adjustment determination and permit modification.

The agency shall set an adjusted opacity standard at the most restrictive level which the performance tests conducted under subpart 1, items A and C demonstrate the emissions unit is capable of meeting and shall modify the permit to establish the adjusted opacity standard, if the requirements of subparts 1 and 2 are met and the stationary source, with the adjusted opacity standard, would meet any one of the following:

B.

have potential emissions of particulate matter of less than 25 tons per year and less than one ton per day; or

C.

contribute less than one µg/m3 to an annual ambient particulate matter standard violation and less than five µg/m3 to a 24-hour ambient particulate matter standard violation.

Statutory Authority:

MS s 116.07

History:

8 SR 2275; L 1987 c 186 s 15; 13 SR 2154; 18 SR 614; 18 SR 1412; 23 SR 1764; 23 SR 2224

Published Electronically:

February 25, 2008

CONTROL OF FUGITIVE PARTICULATE MATTER

7011.0150 PREVENTING PARTICULATE MATTER FROM BECOMING AIRBORNE.

No person shall cause or permit the handling, use, transporting, or storage of any material in a manner which may allow avoidable amounts of particulate matter to become airborne.

No person shall cause or permit a building or its appurtenances or a road, or a driveway, or an open area to be constructed, used, repaired, or demolished without applying all such reasonable measures as may be required to prevent particulate matter from becoming airborne. All persons shall take reasonable precautions to prevent the discharge of visible fugitive dust emissions beyond the lot line of the property on which the emissions originate. The commissioner may require such reasonable measures as may be necessary to prevent particulate matter from becoming airborne including, but not limited to, paving or frequent clearing of roads, driveways, and parking lots; application of dust-free surfaces; application of water; and the planting and maintenance of vegetative ground cover.

Statutory Authority:

MS s 116.07

History:

L 1987 c 186 s 15; 18 SR 614; 20 SR 2316

Published Electronically:

February 25, 2008

7011.0300

[Repealed, 21 SR 693]

Published Electronically:

February 25, 2008

7011.0305

[Repealed, 21 SR 693]

Published Electronically:

February 25, 2008

7011.0310

[Repealed, 21 SR 693]

Published Electronically:

February 25, 2008

7011.0315

[Repealed, 21 SR 693]

Published Electronically:

February 25, 2008

7011.0320

[Repealed, 21 SR 693]

Published Electronically:

February 25, 2008

7011.0325

[Repealed, 21 SR 693]

Published Electronically:

February 25, 2008

7011.0330

[Repealed, 21 SR 693]

Published Electronically:

February 25, 2008

7011.0400

[Repealed, 22 SR 1237]

Published Electronically:

February 25, 2008

7011.0405

[Repealed, 22 SR 1237]

Published Electronically:

February 25, 2008

7011.0410

[Repealed, 22 SR 1237]

Published Electronically:

February 25, 2008

INDIRECT HEATING FOSSIL-FUEL-BURNING EQUIPMENT

7011.0500 DEFINITIONS.

Subpart 1.

Scope.

As used in parts 7011.0500 to 7011.0550, the following words shall have the meanings defined herein.

Subp. 2.

Actual heat input.

"Actual heat input" means the number of Btu per hour (cal/hr) determined by multiplying the gross heating value of the fuel by the rate of fuel burned.

Subp. 3.

Coal refuse.

"Coal refuse" means waste products of coal mining, cleaning, and coal preparation operations (e.g. culm, gob, etc.) containing coal, matrix material, clay, and other organic and inorganic material.

Subp. 4.

Derating.

"Derating" means limitation of heat input and corresponding steam output capacity.

Subp. 5.

Direct heating equipment.

"Direct heating equipment" means a furnace, kiln, dryer, or other combustion equipment used in the burning of a fossil fuel for the purpose of processing a material where the products of combustion have direct contact with the heated material.

Subp. 6.

Distillate oil.

"Distillate oil" means grades of oils known as No. 1 and No. 2, as defined in the A.S.T.M. D 396 (1973).

Subp. 7.

Fossil fuel.

"Fossil fuel" means natural gas, petroleum, coal, wood, peat, and any form of solid, liquid, or gaseous fuel derived from such materials for the purpose of creating useful heat.

Subp. 8.

Gross heating value.

"Gross heating value" means the gross calorific value (cal/g or Btu/1b) of the fuel combusted as determined by A.S.T.M. test methods D 2015-66(72) for solid fuels; D 1826-64(70) for gaseous fuels, and D 240-64(73) for liquid fuels.

Subp. 9.

Indirect heating equipment.

"Indirect heating equipment" means a furnace, a boiler, or other unit of combustion equipment used in the process of burning fossil fuel for the purpose of producing steam, hot water, hot air, or other hot liquid, gas, or solid, where the products of combustion do not have direct contact with the heated medium.

Subp. 10.

Rated heat input.

"Rated heat input" means the number of Btu per hour (cal/hr) which the manufacturer has determined to be the continuous rated capability of the indirect heating equipment, or, where the rated heat input is not specified by the manufacturer, the number of Btu per hour (cal/hr) determined by dividing the rated heat output by the overall thermal efficiency.

Subp. 11.

Residual oil.

"Residual oil" means grades of oils known as No. 4, No. 5 (light), No. 5 (heavy), and No. 6, as listed in A.S.T.M. D 396 (1973).

Subp. 12.

Steam generating unit.

"Steam generating unit" means indirect heating equipment used to produce steam.

Statutory Authority:

MS s 116.07

History:

18 SR 614

Published Electronically:

February 25, 2008

7011.0505 DETERMINATION OF APPLICABLE STANDARDS OF PERFORMANCE.

Subpart 1.

Scope.

Parts 7011.0500 to 7011.0550 shall apply to indirect heating equipment for which a standard of performance has not been promulgated in a specific rule.

Subp. 2.

Rated heat input.

The applicable standards of performance in part 7011.0545 or 7011.0550 shall be determined by using the rated heat input of the specific indirect heating equipment and the total rated heat inputs of all indirect heating equipment and all direct heating equipment of one owner or operator at that particular location.

Subp. 3.

Simultaneous burning of different fuels.

Simultaneous burning of different fuels:

A.

When different fossil fuels are burned simultaneously in any combination, the applicable sulfur dioxide standard shall be determined by proration using the following formula:

| y(a) + z(b) | ||

| w = | _ | |

| x + y + z |

where:

w is the maximum allowable emissions of sulfur dioxide gases in lbs per million Btu (nanograms/joule);

x is the percentage of total heat input derived from gaseous fossil fuel;

y is the percentage of total heat input derived from liquid fossil fuel;

z is the percentage of total heat input derived from solid fossil fuel;

a is the allowable SO2 standard for liquid fossil fuels expressed in lbs per million Btu (nanograms/joule); and

b is the allowable SO2 standard for solid fossil fuels expressed in lbs per million Btu (nanograms/joule).

B.

When different fossil fuels are burned simultaneously in any combination, the applicable nitrogen oxides standard shall be determined by proration using the following formula:

| x(c) + y(a) + z(b) | ||

| w = | _ | |

| x + y + z |

where:

w, x, y, and z mean the same as in the formula in item A, for determining the applicable sulfur dioxide standard;

a is the allowable NOx standard for liquid fossil fuels expressed in lbs per million Btu (nanograms/joule);

b is the allowable NOx standard for solid fossil fuels expressed in lbs per million Btu (nanograms/joule); and

c is the allowable NOx standard for gaseous fossil fuels expressed in lbs per million Btu (nanograms/joule).

Subp. 4.

Exception.

When lignite or a solid fossil fuel containing 25 percent by weight, or more, of coal refuse is burned in combination with gaseous, liquid, or other solid fossil fuel, the standard of performance for nitrogen oxides shall not apply.

Statutory Authority:

MS s 116.07

History:

18 SR 614

Published Electronically:

February 25, 2008

7011.0510 STANDARDS OF PERFORMANCE FOR EXISTING INDIRECT HEATING EQUIPMENT.

Subpart 1.

Particulate matter and sulfur dioxide.

No owner or operator of existing indirect heating equipment shall cause to be discharged into the atmosphere from said equipment any gases which contain particulate matter or sulfur dioxide in excess of the standards of performance shown in part 7011.0545.

Subp. 2.

Opacity.

No owner or operator of existing indirect heating equipment shall cause to be discharged into the atmosphere from said equipment any gases which exhibit greater than 20 percent opacity, except for one six-minute period per hour of not more than 60 percent opacity. An exceedance of this opacity standard occurs whenever any one-hour period contains two or more six-minute periods during which the average opacity exceeds 20 percent or whenever any one-hour period contains one or more six-minute periods during which the average opacity exceeds 60 percent.

Statutory Authority:

MS s 116.07

History:

18 SR 614; 22 SR 1237; 23 SR 145

Published Electronically:

February 25, 2008

7011.0515 STANDARDS OF PERFORMANCE FOR NEW INDIRECT HEATING EQUIPMENT.

Subpart 1.

Particulate matter, sulfur dioxide, and nitrogen oxides.

No owner or operator of new indirect heating equipment shall cause to be discharged into the atmosphere from said equipment any gases which contain particulate matter, sulfur dioxide, or nitrogen oxides in excess of the standards of performance shown in part 7011.0550.

Subp. 2.

Opacity.

No owner or operator of new indirect heating equipment of greater than 250 million Btu per hour rated heat input shall cause to be discharged into the atmosphere from said equipment any gases which exhibit greater than 20 percent opacity, except for one six-minute period per hour of not more than 27 percent opacity. An exceedance of this opacity standard occurs whenever any one-hour period contains two or more six-minute periods during which the average opacity exceeds 20 percent or whenever any one-hour period contains one or more six-minute periods during which the average opacity exceeds 27 percent.

No owner or operator of new indirect heating equipment of 250 million Btu per hour or less rated heat input shall cause to be discharged into the atmosphere from said equipment any gases which exhibit greater than 20 percent opacity; except for one six-minute period per hour of not more than 60 percent opacity. An exceedance of this opacity standard occurs whenever any one-hour period contains two or more six-minute periods during which the average opacity exceeds 20 percent or whenever any one-hour period contains one or more six-minute periods during which the average opacity exceeds 60 percent.

Statutory Authority:

MS s 116.07

History:

18 SR 614; 22 SR 1237; 23 SR 145

Published Electronically:

February 25, 2008

7011.0520 ALLOWANCE FOR STACK HEIGHT FOR INDIRECT HEATING EQUIPMENT.

Subpart 1.

Requirement.

The owner or operator of any indirect heating equipment shall determine and install a stack of such height that will not cause pollutant concentrations at ground levels to exceed any applicable ambient air quality standard or rule.

Subp. 2.

Methodology.

The determination of the ground level concentrations shall be based upon applicable dispersion calculations approved by the agency.

Statutory Authority:

MS s 116.07

History:

18 SR 614

Published Electronically:

February 25, 2008

7011.0525 HIGH HEATING VALUE.

The high heating value of a fossil fuel shall mean the same as the gross heating value.

Statutory Authority:

MS s 116.07

History:

18 SR 614

Published Electronically:

February 25, 2008

7011.0530 PERFORMANCE TEST METHODS.

Unless another method is approved by the commissioner, any person required to submit performance tests for indirect heating equipment shall utilize the following test methods:

Statutory Authority:

MS s 116.07

History:

L 1987 c 186 s 15; 18 SR 614

Published Electronically:

February 25, 2008

7011.0535 PERFORMANCE TEST PROCEDURES.

Subpart 1.

In general.

Performance tests shall be conducted according to the requirements of this part and parts 7017.2001 to 7017.2060.

Subp. 2.

Method 1.

The sampling site, as selected by Method 1, shall be the same for each pollutant during a performance test.

Subp. 3.

Method 5.

For Method 5, the sampling time for each run shall be at least 60 minutes and the minimum sampling volume shall be 0.85 dscm (30 dscf) except that smaller sampling times or volumes, when necessitated by process variables or other factors, may be approved by the agency. The probe and filter holder heating systems in the sampling train shall be set to provide a gas temperature between 120 degrees Celsius and 160 degrees Celsius (250 degrees Fahrenheit and 320 degrees Fahrenheit).

Subp. 4.

Methods 6 and 7.

For Methods 6 and 7, the sampling point in the duct shall be at the center of the cross section or at a point no closer to the walls than 1 m (3.28 feet). For Method 6 the sample shall be extracted at a rate proportional to the gas velocity at the sampling point.

Subp. 5.

Method 6.

For Method 6, the minimum sampling time shall be 20 minutes and the minimum sampling volume 0.02 dscm (0.71 dscf) for each sample. The arithmetic mean of two samples shall constitute one run. Samples shall be taken at approximately 30-minute intervals.

Subp. 6.

Method 7.

For Method 7, each run shall consist of at least four grab samples taken at approximately 15-minute intervals. The arithmetic mean of the samples shall constitute the run value.

Subp. 7.

Nanograms.

For each performance test, the emissions expressed in nanograms/joule (lb/million Btu) shall be determined by the following procedure:

| 20.90 | ||

| E = CF | ( _ ) | |

| 20.9 - %O2 |

where:

C.

%O2 = oxygen content by volume (expressed as percent), dry basis. Percent oxygen shall be determined by using the integrated sampling procedures of Method 3 and by analyzing the sample with a continuous monitoring system, or with the Orsat analyzer. The sample shall be obtained as follows:

(1)

For determination of sulfur dioxide and nitrogen oxides emissions, the oxygen sample shall be obtained at approximately the same point in the duct as used to obtain the samples for Methods 6 and 7 determinations, respectively.

(2)

For determination of particulate emissions, the oxygen sample shall be obtained simultaneously by traversing the duct at the same sampling location used for each run of Method 5 in accordance with Method 1, except that 12 sample points shall be used in all cases;

D.

The owner or operator may use either subitem (1) or (2) to determine the value of F. F = factor representing a ratio of the volume of dry flue gases generated to the calorific value of the fuel combusted.

(1)

Values of F are given as follows:

(a)

for anthracitic coal according to A.S.T.M. D388-66, F = 2.723 x 10-7 dscm/J (10140 dscf/106 Btu);

(b)

for subbituminous and bituminous coal according to A.S.T.M. D388-66, F = 2.637 x 10-7 dscm/J (9820 dscf/106 Btu);

(c)

for liquid fossil fuels including crude, residual, and distillate oils, F = 2.476 x 10-7 dscm/J (9220 dscf/106 Btu); and

(d)

for gaseous fossil fuels including natural gas, propane, and butane, F = 2.347 x 10-7 dscm/J (8740 dscf/106 Btu).

(2)

An owner or operator may use the following equation to determine an F factor (dscf/106 Btu):

| 106[3.64(%H) + 1.53(%C) + 0.57(%S) + 0.14(%N) - 0.46(%O)] | ||

| F = | _ | |

| GVH |

where:

(a)

H, C, S, N, and O are content by weight of hydrogen, carbon, sulfur, nitrogen, and oxygen (expressed as percent), respectively, as determined by ultimate analysis of the fuel fired, dry basis, using A.S.T.M. methods D3168-74 or D3176 (solid fuels) or D240-64(73) (liquid fuels) or computed from results using A.S.T.M. method D1137-53(70), D1945-64(73) or D1946-67(72) (gaseous fuels) as applicable; and

E.

When combinations of fuels are fired, the F factors determined by item C or D shall be prorated in accordance with the following formula:

| xF1 + yF2 + zF3 | ||

| F = | _ | |

| 100 |

where: