Minnesota Administrative Rules

CHAPTER 4732, IONIZING RADIATION

DEPARTMENT OF HEALTH

| Part | Title |

|---|---|

| 4732.0100 | PURPOSE AND SCOPE. |

| 4732.0110 | DEFINITIONS. |

| REGISTRATION REQUIREMENTS | |

| 4732.0200 | REGISTRATION REQUIREMENTS FOR RADIATION-PRODUCING EQUIPMENT AND OTHER ELECTRONIC DEVICES THAT PRODUCE RADIATION. |

| 4732.0210 | REGISTRATION FEES. |

| 4732.0220 | GENERAL REQUIREMENTS FOR ALL FACILITIES. |

| 4732.0250 | RECIPROCITY FOR OUT-OF-STATE RADIATION-PRODUCING EQUIPMENT. |

| 4732.0275 | REGISTRATION OF SERVICE PROVIDERS. |

| 4732.0280 | SERVICE PROVIDER'S RESPONSIBILITY. |

| GENERAL ADMINISTRATION | |

| 4732.0300 | EXEMPTIONS. |

| 4732.0305 | PROHIBITED USES. |

| 4732.0306 | UNAUTHORIZED USES. |

| 4732.0308 | VARIANCE IONIZING RADIATION RULES. |

| 4732.0310 | DATA PRIVACY. |

| 4732.0315 | DELIBERATE MISCONDUCT. |

| 4732.0320 | EMPLOYEE PROTECTION. |

| 4732.0330 | RECORDS. |

| 4732.0335 | INSPECTIONS AND TESTING. |

| 4732.0340 | VIOLATIONS AND ENFORCEMENT REQUIREMENTS. |

| SHIELDING REQUIREMENTS | |

| 4732.0355 | GENERAL REQUIREMENTS FOR SHIELDING AGAINST IONIZING RADIATION. |

| 4732.0360 | SHIELDING PLAN. |

| 4732.0365 | ADDITIONAL SHIELDING REQUIREMENTS FOR DENTAL FACILITIES. |

| 4732.0370 | ADDITIONAL SHIELDING REQUIREMENTS FOR INDUSTRIAL FACILITIES USING RADIATION-PRODUCING EQUIPMENT. |

| 4732.0380 | SHIELDING REQUIREMENTS FOR ACCELERATORS. |

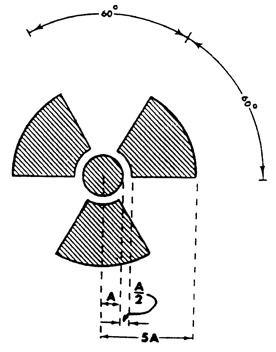

| 4732.0385 | CAUTION SIGNS. |

| DOSE LEVELS | |

| 4732.0400 | DETERMINATION OF ACCUMULATED OCCUPATIONAL DOSE. |

| 4732.0410 | OCCUPATIONAL DOSE LIMITS FOR ADULTS. |

| 4732.0415 | DOSE EQUIVALENT TO AN EMBRYO OR FETUS. |

| 4732.0420 | EXPOSURE OF MINORS. |

| 4732.0425 | PLANNED SPECIAL EXPOSURES. |

| 4732.0430 | DOSE LIMITS FOR INDIVIDUAL MEMBERS OF THE PUBLIC. |

| 4732.0440 | INDIVIDUAL MONITORING. |

| RADIATION SAFETY REQUIREMENTS | |

| 4732.0500 | REGISTRANT'S SAFETY RESPONSIBILITIES. |

| 4732.0505 | RADIATION SAFETY OFFICER RESPONSIBILITIES. |

| 4732.0510 | PROCEDURES AND SAFETY INSTRUCTION FOR FACILITIES. |

| 4732.0520 | QUALITY ASSURANCE PROGRAM. |

| 4732.0530 | ALARA PROGRAM. |

| 4732.0535 | RETAKE OR REJECT ANALYSIS PROGRAM. |

| 4732.0540 | RADIATION PROGRAM AUDITS. |

| 4732.0545 | UTILIZATION LOG. |

| 4732.0550 | RADIOLOGICAL PRACTICE STANDARDS. |

| 4732.0555 | X-RAY FILM PROCESSING REQUIREMENTS. |

| 4732.0560 | ORDERING OF DIAGNOSTIC RADIOGRAPHIC OR THERAPEUTIC PROCEDURES. |

| 4732.0565 | HEALING ARTS SCREENING. |

| 4732.0570 | OPERATOR REQUIREMENTS. |

| 4732.0575 | EXAMINATION REQUIREMENTS. |

| 4732.0580 | REGISTRANT REQUIREMENTS FOR OPERATORS IN FACILITIES USING X-RAY EQUIPMENT. |

| 4732.0585 | EQUIVALENT EXAMINATIONS. |

| 4732.0590 | INDIVIDUALS OPERATING X-RAY EQUIPMENT DURING TRAINING. |

| REPORTS AND NOTIFICATIONS | |

| 4732.0600 | REPORTS OF THEFT OR LOSS OF RADIATION-PRODUCING EQUIPMENT. |

| 4732.0610 | REPORTS OF MEDICAL EVENTS OR INCIDENTS INVOLVING RADIATION-PRODUCING EQUIPMENT. |

| 4732.0620 | WARNING AND CONTROL DEVICES FOR HIGH AND VERY HIGH RADIATION AREAS. |

| 4732.0630 | BYPASSING A SAFETY DEVICE. |

| CALIBRATIONS AND MEASUREMENT INSTRUMENTS | |

| 4732.0700 | CALIBRATIONS. |

| 4732.0710 | RADIATION SURVEY OR MEASUREMENT INSTRUMENTS. |

| EQUIPMENT REQUIREMENTS | |

| 4732.0800 | GENERAL EQUIPMENT REQUIREMENTS FOR ALL DIAGNOSTIC RADIATION-PRODUCING SYSTEMS. |

| 4732.0820 | GENERAL PURPOSE DIAGNOSTIC RADIATION-PRODUCING EQUIPMENT MANUFACTURED BEFORE 1973. |

| 4732.0825 | FLUOROSCOPIC X-RAY SYSTEMS EXCEPT RADIATION THERAPY SIMULATORS. |

| 4732.0830 | FLUOROSCOPIC DOSE-AREA-PRODUCT MONITOR. |

| 4732.0835 | REQUIREMENTS FOR COMPUTED RADIOGRAPHY, DIGITAL RADIOGRAPHY, OR PHOTOSTIMULABLE STORAGE PHOSPHOR RADIATION-PRODUCING EQUIPMENT. |

| 4732.0850 | BONE DENSITOMETRY SYSTEMS. |

| 4732.0860 | COMPUTED TOMOGRAPHY REQUIREMENTS. |

| 4732.0865 | COMPUTERIZED TOMOGRAPHY DESIGNED FOR VISUALIZATION OF THE HEAD AND SOFT TISSUE OF THE NECK. |

| 4732.0870 | REQUIREMENTS FOR STEREOTACTIC MAMMOGRAPHIC EQUIPMENT. |

| 4732.0875 | VETERINARY MEDICAL RADIOGRAPHIC SYSTEMS. |

| 4732.0880 | INTRAORAL DENTAL RADIOGRAPHIC SYSTEMS. |

| 4732.0890 | EXTRAORAL DENTAL SYSTEMS. |

| 4732.0895 | DENTAL COMPUTED TOMOGRAPHY SYSTEMS. |

| RADIATION THERAPEUTIC REQUIREMENTS | |

| 4732.0900 | GENERAL REQUIREMENTS FOR FACILITIES USING ACCELERATORS. |

| 4732.0925 | GENERAL REQUIREMENTS FOR THERAPEUTIC EQUIPMENT. |

| 4732.0930 | THERAPEUTIC RADIATION MACHINES OF LESS THAN 500 KV. |

| 4732.0940 | THERAPEUTIC RADIATION MACHINES - PHOTON THERAPY SYSTEMS (500 KV AND ABOVE) AND ELECTRON THERAPY SYSTEMS (500 KEV AND ABOVE). |

| 4732.1000 | REQUIREMENTS FOR X-RAY FLUORESCENT ANALYZERS AND BOMB DETECTION UNITS. |

| 4732.1040 | INDUSTRIAL FACILITY REQUIREMENTS FOR USING RADIATION-PRODUCING EQUIPMENT IN MANUFACTURING PROCESSES, GAUGES, AND CABINETS. |

| 4732.1050 | REQUIREMENTS FOR PERMANENT INDUSTRIAL RADIOGRAPHIC INSTALLATIONS. |

| 4732.1055 | INDUSTRIAL RADIOGRAPHIC OPERATING AND EMERGENCY PROCEDURES. |

| 4732.1058 | INDUSTRIAL RADIOGRAPHY IN A TEMPORARY JOB SITE. |

| 4732.1060 | INSTRUCTION AND TRAINING FOR INDUSTRIAL RADIOGRAPHY. |

| 4732.1063 | WARNING DEVICES FOR INDUSTRIAL RADIOGRAPHY FACILITIES. |

| 4732.1065 | POSTING REQUIREMENTS FOR INDUSTRIAL RADIOGRAPHY. |

| 4732.1067 | SURVEILLANCE FOR INDUSTRIAL RADIOGRAPHY. |

| 4732.1070 | RADIOGRAPHER CERTIFICATION. |

| 4732.1100 | INSTALLATION CALIBRATION TESTS AND EQUIPMENT PERFORMANCE TESTS FOR A QUALITY ASSURANCE PROGRAM. |

| 4732.1120 | THERAPEUTIC EQUIPMENT PERFORMANCE TESTS AND LIMITS FOR MEASUREMENT EQUIPMENT. |

| 4732.1130 | EQUIPMENT PERFORMANCE TESTS FOR EXTERNAL BEAM TELETHERAPY AND SIMULATION SYSTEMS. |

4732.0100 PURPOSE AND SCOPE.

Subpart 1.

Purpose.

The purpose of this chapter is to control and prevent hazards to health and safety from ionizing radiation without limiting or interfering with its constructive uses.

Subp. 2.

Scope.

Except as otherwise specified, this chapter applies to all persons who receive, possess, use, transfer, own, or acquire any radiation-producing equipment. The scope of this chapter does not include those sources of ionizing radiation known as radioactive materials, which are covered under chapter 4731.

Subp. 3.

Additional requirements.

In addition to the requirements established in this chapter, the commissioner must impose upon any registrant any requirements deemed appropriate or necessary to minimize danger to public health and safety.

Statutory Authority:

MS s 144.12

History:

32 SR 777

Published Electronically:

December 10, 2007

4732.0110 DEFINITIONS.

Subpart 1.

Scope.

For purposes of this chapter, the terms in this part have the meanings given them.

Subp. 2.

Absorbed dose.

"Absorbed dose" means the energy imparted by ionizing radiation per unit mass of irradiated material. The special unit of absorbed dose is the rad under the conventional system of measurement and is the gray under the SI system of measurement.

Subp. 3.

Absorbed dose rate.

"Absorbed dose rate" means absorbed dose per unit time for machine with timers, or dose-monitor unit per unit time for linear accelerators.

Subp. 4.

Accelerator.

"Accelerator" means any machine capable of accelerating electrons, protons, deuterons, or other charged particles in a vacuum and of discharging the resultant particulate or other radiation into a medium at energies usually in excess of 1 MeV. For purposes of this definition, linear accelerator, particle accelerator, and cyclotron are equivalent terms.

Subp. 5.

Added filtration.

"Added filtration" means filtration that is in addition to the inherent filtration.

Subp. 7.

Air kerma (K).

"Air kerma (K)" means the kinetic energy released in air by ionizing radiation. Kerma is determined as the quotient of dE by dM, where dE is the sum of the initial kinetic energies of all the charged ionizing particles liberated by uncharged ionizing particles in air of mass dM. The special name for the unit of kerma is the gray (Gy). The SI unit is joule per kilogram.

Subp. 8.

Aluminum equivalent.

"Aluminum equivalent" means the thickness of type 1100 aluminum alloy affording the same attenuation, under specified conditions, as the material in question.

Subp. 9.

Annual.

"Annual" means an activity is done or is performed at intervals not to exceed 12 months.

Subp. 10.

Appropriate limit or appropriate limits.

"Appropriate limit" or "appropriate limits" means the maximum permissible dose or doses of radiation that may be administered to the whole body or a given part of a human being.

Subp. 11.

As low as reasonably achievable or ALARA.

"As low as reasonably achievable" or "ALARA" means making every reasonable effort to maintain exposure to radiation as far below the dose limits as is practical, consistent with the purpose for which the registered activity is undertaken, taking into account the state of technology, the economics of improvement in relation to benefits to the public health and safety, and other societal and socioeconomic considerations.

Subp. 12.

Attenuation.

"Attenuation" means the reduction of exposure rate upon passage of radiation through matter.

Subp. 13.

Attenuation block.

"Attenuation block" means a block or stack, having dimensions 20 centimeters or larger by 20 centimeters or larger by 3.8 centimeters, of type 1100 aluminum alloy or other materials having equivalent attenuation that is large enough to intercept the entire x-ray beam.

Subp. 14.

Audit.

"Audit" means a planned and documented activity performed according to procedures to determine, by examination and evaluation of objective evidence, the adequacy of and extent to which applicable elements of the quality assurance program have been developed, documented, and effectively implemented.

Subp. 15.

Automatic exposure control or AEC.

"Automatic exposure control" or "AEC" means a device that automatically controls one or more technique factors in order to obtain a required quantity of radiation at a preselected location or locations.

Subp. 16.

Base plus fog density.

"Base plus fog density" means the optical density of a film due to its base density plus any action of the developer on the unexposed silver halide crystals.

Subp. 17.

Beam axis.

"Beam axis" means a line from the source through the centers of the x-ray fields, or for therapy the axis of rotation of the beam-limiting device.

Subp. 18.

Beam-limiting device or BLD.

"Beam-limiting device" or "BLD" means a device used to restrict the dimensions of the x-ray field or useful beam.

Subp. 19.

Beam-monitoring system.

"Beam-monitoring system" means a system designed and installed to detect and measure the radiation present in the useful beam.

Subp. 20.

Beam-scattering filter or foil.

"Beam-scattering filter" or "foil" means a thin piece of material, usually metallic, placed in the beam to scatter a beam of electrons in order to provide a more uniform electron distribution in the useful beam.

Subp. 21.

Bent beam linear accelerator.

"Bent beam linear accelerator" means a linear accelerator geometry in which the accelerated electron beam must change direction by passing through a bending magnet.

Subp. 22.

Bone densitometry system.

"Bone densitometry system" means a medical device that uses electronically produced ionizing radiation to determine the density of bone structures of human patients.

Subp. 23.

C-arm system.

"C-arm system" means an x-ray system in which the image receptor and the x-ray tube housing assembly are connected by a common mechanical support system to maintain a desired spatial relation.

Subp. 24.

Cabinet x-ray system.

"Cabinet x-ray system" means an x-ray system with the x-ray tube installed in an enclosure independent of existing architectural structure except the floor on which it may be placed. The cabinet x-ray system is intended to:

C.

exclude personnel from its interior during generation of radiation.

Included are all x-ray systems designed primarily for the inspection of carry-on baggage at airline, railroad, and bus terminals and in similar facilities. An x-ray tube used within a shielded part of a building or x-ray equipment that may temporarily or occasionally incorporate portable shielding is not considered a cabinet x-ray system.

Subp. 25.

Calibration.

"Calibration" means:

A.

the determination of the response or reading of an instrument relative to a series of known radiation values over the range of the instrument;

B.

the determination of the radiation dose or exposure rate at a designated distance from a radiation source under specified conditions of measurement;

C.

to check, adjust, or systematically standardize to graduations of a quantitative measuring instrument; and

D.

to check, adjust, or systematically bring radiation-producing equipment into manufacturer's specifications.

Subp. 26.

Cephalometric device.

"Cephalometric device" means a device intended for the radiographic visualization and measurement of the dimensions of the human head.

Subp. 27.

Certified cabinet x-ray system.

"Certified cabinet x-ray system" means an x-ray system that has been certified according to Code of Federal Regulations, title 21, section 1010.2, as being manufactured and assembled pursuant to Code of Federal Regulations, title 21, section 1020.40.

Subp. 28.

Certified components.

"Certified components" means components of x-ray systems that are subject to the x-ray equipment performance standards adopted under Public Law 90-602, the Radiation Control for Health and Safety Act of 1968.

Subp. 29.

Certified system.

"Certified system" means an x-ray system that has one or more certified components.

Subp. 30.

Changeable filters.

"Changeable filters" means any filter, exclusive of inherent filtration, that can be removed from the useful beam through any electronic, mechanical, or physical process.

Subp. 31.

Clinical range.

"Clinical range" means the range of control console technique settings that a facility would use in its routine x-ray projections. Equipment performance tests are performed over clinical ranges.

Subp. 32.

Coefficient of variation or C.

"Coefficient of variation" or "C" means the standard deviation divided by the average of the parameters measured.

Subp. 33.

Collimation.

"Collimation" means the restriction of the useful beam to an appropriate area.

Subp. 34.

Collimator.

"Collimator" means a device used to limit the size, shape, and direction of the primary beam.

Subp. 36.

Computed radiography.

"Computed radiography" means a system of creating digital radiographic images that utilizes a storage-phosphor plate instead of film in a cassette. Once the plate is exposed, a laser beam scans it to produce the digital data that is translated into an image.

Subp. 37.

Computed tomography or CT.

"Computed tomography" or "CT" means the production of a tomogram by the acquisition and computer processing of x-ray transmission data.

Subp. 38.

Control panel.

"Control panel" means the part of the x-ray control upon which the switches, knobs, push buttons, and other hardware necessary for manually setting the technique factors are mounted.

Subp. 39.

CT conditions of operation.

"CT conditions of operation" means all selectable parameters governing the operation of a CT system including, but not limited to, nominal tomographic section thickness, filtration, and the technique factors defined in subpart 195.

Subp. 40.

CT dose index or CTDI.

"CT dose index" or "CTDI" means the integral from minus 7T to plus 7T of the dose profile along a line perpendicular to the tomographic plane divided by the product of the nominal tomographic section thickness (T) and the number of tomograms produced in a single scan (n), that is:

| CTDI | = | 1/nT | -7T∫+7T | D(z) | dz |

where:

z = position along a line perpendicular to the tomographic plane;

D(z) = dose at position z;

T = nominal tomographic section thickness; and

n = number of tomograms produced in a single scan.

This definition assumes that the dose profile is centered around z=0 and that, for a multiple tomogram system, the increment of adjacent scans is nT.

Subp. 41.

CT gantry.

"CT gantry" means the tube housing assemblies, beam-limiting devices, and detectors, as well as the supporting structures and frames that hold those components.

Subp. 42.

CT number.

"CT number" means the number used to represent the x-ray attenuation associated with each elemental area of the CT image.

Subp. 43.

CT scan.

"CT scan" means the complete process of collecting x-ray transmission data for the production of a tomogram. This includes data collected simultaneously during a single scan for the production of one or more tomogram.

Subp. 44.

CT scan increment.

"CT scan increment" means the amount of relative displacement of the patient with respect to the CT system between successive scans measured along the direction of the displacement.

Subp. 45.

CT scan time.

"CT scan time" means the time between the beginning and end of x-ray transmission data accumulation for a CT scan.

Subp. 46.

Dead-man switch.

"Dead-man switch" means a switch so constructed that a circuit-closing contact can be maintained only by continuous pressure on the switch by the operator.

Subp. 47.

Declared pregnant woman.

"Declared pregnant woman" means a woman who has voluntarily informed the registrant, in writing, of her pregnancy and the estimated date of conception. The declaration remains in effect until the declared pregnant woman withdraws the declaration in writing or is no longer pregnant.

Subp. 48.

Densitometer.

"Densitometer" means an instrument that measures the degree of blackening or radiographic density of a film due to radiation or light by measuring the ratio of the light intensity incident on the film to the light intensity transmitted by the film.

Subp. 49.

Diagnostic radiological physicist.

"Diagnostic radiological physicist" means an individual who is qualified to practice independently in the appropriate subfields for medical diagnostic physics and is:

A.

certified in radiological physics or diagnostic radiological physics by the American Board of Radiology;

D.

a holder of a masters degree in medical physics, radiological sciences, or an equivalent field involving graduate study in physics applied to the application of radiation to humans from an accredited college or university and has at least two years of full-time practical training or supervised experience under an individual who meets the qualifications in item A, B, or C.

Subp. 50.

Diagnostic x-ray imaging system.

"Diagnostic x-ray imaging system" means an assemblage of components for the generation, emissions, and reception of x-rays and the transformation, storage, and visual display of the resultant x-ray image which are designed and used for irradiation of any part of a body for the purpose of diagnosis or visualization.

Subp. 51.

Digital radiography.

"Digital radiography" means a radiographic image displayed on a video monitor after computer processing.

Subp. 52.

Direct supervision.

"Direct supervision" means guidance and instruction by a qualified individual who is physically present and watching the performance of the radiological operation or procedure and in such proximity that contact can be maintained and immediate assistance can be given as required.

Subp. 53.

Dose.

"Dose" means absorbed radiation dose, radiation dose equivalent, effective radiation dose equivalent, committed radiation dose equivalent, committed effective radiation dose equivalent, or total effective radiation dose equivalent. For purposes of this chapter, "radiation dose" is an equivalent term.

Subp. 54.

Dose equivalent or DE.

"Dose equivalent" or "DE" means a quantity used for radiation protection purposes that expresses on a common scale for all radiations the irradiation incurred by exposed persons. It is defined as the product of the absorbed radiation dose and the quality factor. For x-rays and gamma rays, the dose equivalent in rem is usually assumed to be numerically equal to either the exposure in roentgens or the absorbed dose in rad. The special unit radiation dose equivalent is the rem under the conventional measurement system and is the sievert under the SI measurement system.

Subp. 55.

Dose limits or limits.

"Dose limits" or "limits" means the permissible upper bounds of radiation doses.

Subp. 56.

Dose-monitoring system.

"Dose-monitoring system" means a system of devices for the detection, measurement, and display of quantities of radiation that can be related to the absorbed dose at a given location within a defined geometry.

Subp. 57.

Dose-monitor unit.

"Dose-monitor unit" means a unit response from the dose-monitoring system from which the absorbed radiation dose has been calculated.

Subp. 58.

Effective dose equivalent or HE.

"Effective dose equivalent" or "HE" means the sum of the products of the dose equivalent to each organ or tissue (HT) and the weighting factor (wT) applicable to each of the body organs or tissues that are irradiated.

Subp. 59.

Electron-beam generator.

"Electron-beam generator" means a type of electron accelerator in which the electron beam is brought out into the atmosphere for irradiation purposes.

Subp. 60.

Electronic signature.

"Electronic signature" means an electronic sound, symbol, or process attached to or logically associated with a record, and executed or adopted by a person with the intent to sign the record according to Minnesota Statutes, chapter 325L.

Subp. 61.

Exposure.

"Exposure" means being exposed to ionizing radiation. The unit of exposure is the Roentgen in air (R). The SI unit is 2.58 x 10-4 coulombs per kilogram.

Subp. 62.

Exposure rate.

"Exposure rate" means the exposure per unit of time, such as roentgen per minute, milliroentgen per hour. The SI unit is 10-4 coulombs per kilogram per hour.

Subp. 63.

External beam radiation therapy.

"External beam radiation therapy" means therapeutic irradiation in which the source of radiation is at a distance from the body.

Subp. 64.

Facility.

"Facility" means the location at which one or more sources of radiation are installed or located within one building, one vehicle, at one address, and are under the same administrative control.

Subp. 65.

Field emission equipment.

"Field emission equipment" means equipment that uses an x-ray tube in which electron emission from the cathode is due solely to the action of an electric field.

Subp. 66.

Field-flattening filter.

"Field-flattening filter" means a filter used to homogenize the absorbed dose rate over the radiation field.

Subp. 67.

Filmless radiography or photostimulable storage phosphor (PSP) imaging.

"Filmless radiography" or "photostimulable storage phosphor (PSP) imaging" means a system that could employ reusable imaging plates, associated hardware and software to acquire and display digital projection radiographs. These imaging devices are known by a number of names including computed radiography (CR), photostimulable storage phosphor (PSP) imaging, or digital radiography (DR). In the digital form, PSP images are readily put into picture archiving and communications systems and viewed on a monitor rather than viewing an image on x-ray film.

Subp. 68.

Filter or filtration.

"Filter" or "filtration" means material placed in the useful beam to preferentially absorb selected radiations.

Subp. 69.

Fluoroscopic imaging assembly.

"Fluoroscopic imaging assembly" means a subsystem in which x-ray photons produce a set of fluoroscopic or radiographic recorded images from the fluoroscopic image receptor. Fluoroscopic imaging assembly includes image receptors such as the image intensifier and spot-film device, electrical interlocks, if any, and structural material providing linkage between the image receptor and diagnostic source assembly.

Subp. 70.

Focal spot.

"Focal spot" means the area of the anode of the x-ray tube bombarded by the electrons accelerated from the cathode and from which the useful beam originates.

Subp. 71.

Gantry.

"Gantry" means the part of the system supporting and allowing possible movements of the radiation head.

Subp. 72.

General purpose radiographic x-ray system.

"General purpose radiographic x-ray system" means a radiographic x-ray system that, by design, is not limited to radiographic examination of specific anatomical regions.

Subp. 74.

Gray or Gy.

"Gray" or "Gy" means the unit of absorbed radiation dose equal to one joule per kilogram. The conventional system equivalent is 100 rad.

Subp. 75.

Half-value layer or HVL.

"Half-value layer" or "HVL" means the thickness of a specified material that attenuates the beam of radiation to such an extent that the exposure rate is reduced to one-half of its original value. The contribution of all scattered radiation, other than any that might be present initially in the beam concerned, is considered excluded.

Subp. 76.

Healing arts.

"Healing arts" means health professions for diagnostic or healing treatment of human and animal maladies that are regulated under Minnesota Statutes, chapter 147, 153, or 156; or section 148.01, 148.106, or 150A.05, subdivision 1, clause (4), for the lawful practice of medicine, dentistry, veterinary medicine, osteopathic medicine, chiropractic, and podiatry.

Subp. 77.

Healing arts screening or screening.

"Healing arts screening" or "screening" means the testing of individuals with x-ray equipment to detect or evaluate health conditions when the tests are not specifically and individually ordered by a licensed practitioner of the healing arts who is legally authorized to prescribe the tests for the purpose of diagnosis or treatment.

Subp. 78.

High radiation area.

"High radiation area" means any area, accessible to individuals, in which radiation levels from radiation sources external to the body could result in an individual receiving a radiation dose equivalent in excess of 0.1 rem (1.0 mSv) in one hour at 30 centimeters from any source of radiation or 30 centimeters from any surface that the radiation penetrates.

Subp. 79.

Image intensifier.

"Image intensifier" means a device, installed in its housing, that instantaneously converts an x-ray pattern into a corresponding light image of higher energy intensity.

Subp. 80.

Image quality.

"Image quality" means the overall clarity and detail of a radiographic image. Limiting spatial resolution (or resolving power), image sharpness, and image contrast are three common measures of image quality.

Subp. 81.

Image receptor.

"Image receptor" means a device such as a fluorescent screen or radiographic film, solid-state detector, or gaseous detector that transforms incident x-ray photons either into a visible image or into another form that can be made into a visible image by further transformations.

Subp. 83.

Individual monitoring.

"Individual monitoring" means the assessment of dose equivalent by the use of individual monitoring devices or by the use of radiation survey data.

Subp. 84.

Individual monitoring devices.

"Individual monitoring devices" means devices designed to be worn by a single individual for the assessment of dose equivalent. For purposes of this chapter, "personal dosimeter" and "dosimeter" are equivalent terms. Examples of individual monitoring devices are film badges, thermoluminescent devices, pocket ionization chambers, and optically stimulated luminescence devices.

Subp. 85.

Industrial cabinet baggage system.

"Industrial cabinet baggage system" has the meaning given for cabinet x-ray systems in subpart 24.

Subp. 86.

Industrial vault radiography.

"Industrial vault radiography" means industrial radiography conducted in an enclosure, shielded so that radiation levels at every location on the exterior meet the unrestricted limitations in this chapter.

Subp. 87.

Industrial radiographer.

"Industrial radiographer" means any individual who performs or who, in attendance at the site where ionizing radiation sources are being used, personally supervises industrial radiographic operations and who is responsible to the registrant for ensuring compliance with this chapter.

Subp. 88.

Industrial radiographer's assistant.

"Industrial radiographer's assistant" means an individual who uses radiographic exposure devices or radiation survey instruments in industrial radiography under the supervision of an industrial radiographer.

Subp. 89.

Industrial radiography.

"Industrial radiography" means an examination of the structure of materials by the nondestructive methods of utilizing ionizing radiation to make images. Industrial radiography does not include cabinet x-ray or the use of ionizing radiation-producing equipment to measure thickness, to identify levels and material in containers, or to analyze the chemical compositions. Industrial x-ray does not include the use of ionizing radiation-producing equipment in forensic, medical, or veterinary research.

Subp. 90.

Inherent filtration.

"Inherent filtration" means the filtration of the useful beam provided by the permanently installed components of the tube housing assembly.

Subp. 91.

Inspection.

"Inspection" means an official examination or observation, including but not limited to tests, radiation surveys, and monitoring to determine compliance with rules, regulations, and requirements of the commissioner.

Subp. 92.

Instrument traceability.

"Instrument traceability" for ionizing radiation measurements means the ability to show that an instrument has been calibrated at specified time intervals using a national standard or a transfer standard. If a transfer standard is used, the calibration must be at a laboratory accredited by a program that requires continuing participation in measurement quality assurance with the National Institute of Standards and Technology (NIST), or other equivalent national or international programs.

Subp. 93.

Interlock.

"Interlock" means a device that automatically causes a reduction of the exposure rate upon entry by personnel into a high radiation area. An interlocking device must prevent the start or continued operation of equipment unless certain predetermined conditions prevail.

Subp. 94.

Ionizing radiation.

"Ionizing radiation" means any radiation capable of producing displacing electrons from atoms or molecules, thereby producing ions. Examples: alpha, beta, gamma, x-ray, and neutron radiation.

Subp. 95.

Irradiation.

"Irradiation" means the exposure of a living being or matter to ionizing radiation.

Subp. 96.

Isocenter.

"Isocenter" means a fixed point in space through which pass the central axes of radiation beams for all possible beam orientations and field sizes.

Subp. 97.

Kilovolt peak or kVp.

"Kilovolt peak" or "kVp" has the meaning given for peak tube potential in subpart 120.

Subp. 98.

Lead equivalence or lead equivalent.

"Lead equivalence" or "lead equivalent" means the thickness of lead affording the same attenuation, under specified conditions, as the material in question.

Subp. 99.

Leakage radiation.

"Leakage radiation" means radiation emanating from the radiation source assembly except for the useful beam and radiation produced when the exposure switch or timer is not activated.

Subp. 100.

Leakage technique factors.

"Leakage technique factors" means the technique factors associated with the diagnostic or therapeutic source assembly that are used in measuring leakage radiation.

Subp. 101.

Licensed practitioner of the healing arts.

"Licensed practitioner of the healing arts" means health professionals for diagnostic or healing treatment of human and animal maladies, which are licensed under Minnesota Statutes, chapter 147, 153, or 156; or section 148.01, 148.106, or 150A.05, subdivision 1, clause (4), for the lawful practice of medicine, dentistry, veterinary medicine, osteopathic medicine, chiropractic, and podiatry.

Subp. 102.

Light field.

"Light field" means the area of the intersection of the light beam from the beam-limiting device and one of the set of planes parallel to and including the plane of the image receptor whose perimeter is the locus of points at which the illumination is one-fourth of the maximum in the intersection.

Subp. 103.

Line-voltage regulation.

"Line-voltage regulation" means the difference between the no-load and the load line potentials expressed as a percent of the load line potential. It is calculated using the following equation:

Percent line-voltage regulation = 100 (Vn - V1)/V1

| where: |

| Vn = no-load line potential; and |

| V1 = load line potential. |

Subp. 106.

Maximum line current.

"Maximum line current" means the root-mean-square current in the supply line of an x-ray system operating at its maximum rating.

Subp. 107.

Medical event.

"Medical event" means the administration of radiation received from radiation-producing equipment and includes:

A.

therapeutic administration involving:

(3)

a dose to tissue other than the treatment site that is 50 percent or more of the dose expected from the administration defined in the written directive;

(5)

a total radiation dosage delivered that differs from the prescribed dosage by 20 percent or more or falls outside the prescribed dosage range; or

(6)

a fractionated radiation dose delivered that differs from the prescribed dose, for a single fraction, by 50 percent or more; and

Subp. 108.

Medical particle accelerator.

"Medical particle accelerator" has the meaning given for accelerator in subpart 4.

Subp. 109.

Medical physicist.

"Medical physicist" has the meaning given for diagnostic radiological physicist in subpart 49, or therapeutic radiological physicist in subpart 200.

Subp. 110.

Medical uses.

"Medical uses" means the intentional internal or external administration of radiation to human and animal patients or human research subjects.

Subp. 111.

Megavolt (MV) or mega electron volt (MeV).

"Megavolt," "MV," or "mega electron volt," "MeV," means the energy equal to that acquired by a particle with one electron charge in passing through a potential difference of 1,000,000 volts in a vacuum. Current convention is to use MV for photons and MeV for electrons.

Subp. 112.

Moving beam radiation therapy.

"Moving beam radiation therapy" means radiation therapy with continuous displacement of one or more mechanical axes relative to the patient during irradiation. It includes arc therapy, skip therapy, conformal therapy, and rotational therapy.

Subp. 113.

Nominal tomographic section thickness.

"Nominal tomographic section thickness" means the full width at half-maximum at the center of the cross-sectional volume over which x-ray transmission data are collected.

Subp. 114.

Nominal treatment distance.

"Nominal treatment distance" means:

A.

for electron irradiation, the distance from the scattering foil, virtual source, or exit window of the electron beam to the entrance surface of the irradiated object along the central axis of the useful beam;

B.

for x-ray irradiation, the virtual source or target to isocenter distance along the central axis of the useful beam; and

Subp. 115.

Nonstochastic effects.

"Nonstochastic effects" means health effects the severity of which varies with the radiation dose, and for which a threshold is believed to exist. Radiation-induced cataract formation is an example of a nonstochastic effect.

Subp. 116.

Occupational dose.

"Occupational dose" means the dose received by an individual in the course of employment in which the individual's assigned duties for the registrant involve exposure to radiation-producing equipment, whether or not the radiation-producing equipment is in the possession of the registrant. Occupational dose does not include doses received from background radiation, from any medical administration the individual has received, from exposure to individuals administered radioactive material and released in accordance with chapter 4731, from voluntary participation in medical research programs, or as a member of the public.

Subp. 117.

Open-beam configuration.

"Open-beam configuration" means an analytical x-ray system in which an individual could accidentally place some part of the body in the primary beam or secondary scattered beam path during normal operation.

Subp. 118.

Optical density or O.D.

"Optical density" or "O.D." means the logarithm of the incident light intensity minus the logarithm of the transmitted light intensity.

Subp. 119.

Patient.

"Patient" means an individual or animal subjected to healing arts examination, diagnosis, or treatment.

Subp. 120.

Peak tube potential.

"Peak tube potential" means the maximum value of the potential difference across the x-ray tube during an exposure.

Subp. 121.

Permanent radiographic installation.

"Permanent radiographic installation" means a shielded enclosed room, cell, vault, or structure that is not moved and is not located at a temporary job site. The installation is designed or intended for radiography, and in which radiography is regularly performed.

Subp. 122.

Person.

"Person" means any individual, corporation, partnership, firm, association, trust, estate, public or private institution, group, agency, political subdivision of this state, and any legal successor, representative, agent or agency of the foregoing, excluding federal government agencies.

Subp. 123.

Personal protective garments.

"Personal protective garments" mean garments, including aprons, gloves, and thyroid collars made of radiation absorbing materials used to reduce radiation exposure.

Subp. 124.

Personal monitoring dosimeter.

"Personal monitoring dosimeter" has the meaning given for individual monitoring devices in subpart 84.

Subp. 125.

Phantom.

"Phantom" means a volume of material behaving in a manner similar to tissue with respect to the attenuation and scattering of radiation.

Subp. 126.

Phototimer.

"Phototimer" means a method for controlling radiation exposures to image receptors by measuring the amount of radiation that reaches a radiation monitoring device. A radiation monitoring device is part of an electronic circuit that controls the duration of time the x-ray tube is activated. "Phototimer" includes the meaning given for automatic exposure control in subpart 15.

Subp. 126a.

Physician assistant.

"Physician assistant" means a person registered according to Minnesota Statutes, chapter 147A, who is qualified by academic, practical training, or both to provide patient services as specified in the physician-physician assistant agreement recognized by the Minnesota Board of Medical Practice.

Subp. 127.

Pixel or picture element.

"Pixel" or "picture element" means an elemental area of a digital image.

Subp. 128.

Port film or portal imaging.

"Port film" or "portal imaging" means a radiographic film or electronic image taken with a therapeutic x-ray system to verify proper setup of the treatment field.

Subp. 129.

Positive beam limiting or limitation or PBL.

"Positive beam limiting or limitation" or "PBL" means the automatic or semiautomatic adjustment of an x-ray beam to the size of the selected image receptor, whereby exposures cannot be made without this adjustment.

Subp. 130.

Position-indicating device or PID.

"Position-indicating device" or "PID" means a device on dental x-ray equipment used to indicate the beam position and to establish the source-to-skin distance.

Subp. 131.

Prescribed dose.

"Prescribed dose" means the total radiation dose and radiation dose per fraction as documented in the written directive or therapeutic order.

Subp. 132.

Primary beam.

"Primary beam" means radiation that passes through an aperture of the source housing by a direct path from the x-ray tube located in the radiation-producing equipment housing.

Subp. 133.

Primary dose-monitoring system.

"Primary dose-monitoring system" means a system that will monitor the useful beam during irradiation and will terminate irradiation when a preselected number of dose monitor units have been acquired.

Subp. 134.

Primary protective barrier.

"Primary protective barrier" means the material, excluding filters, placed in the useful beam for protection purposes to reduce the radiation exposure.

Subp. 136.

Protective barrier or barrier.

"Protective barrier" or "barrier" means a barrier of radiation absorbing materials used to reduce radiation exposure.

Subp. 138.

Pulsed mode.

"Pulsed mode" means operation of an x-ray system so that the x-ray tube current is pulsed by the x-ray control to produce one or more exposure intervals of less than one-half second duration.

Subp. 139.

Quality assurance program.

"Quality assurance program" means an all-encompassing program including quality control that extends to administrative, education, and preventive maintenance methods. It includes a continuing evaluation of the adequacy and effectiveness of the overall imaging program, with a view to initiating corrective measures when necessary. The nature and extent of this program will vary with the size and type of the facility, and the type of activities conducted.

Subp. 140.

Quality control.

"Quality control" means a series of distinct technical procedures that ensure the production of a satisfactory product. Its aim is to provide quality that is not only satisfactory but also dependable and economic. The quality control procedures are concerned directly with the equipment.

Subp. 144.

Radiation area.

"Radiation area" means an area accessible to individuals in which the radiation levels could result in an individual receiving a dose equivalent in excess of 0.005 rem (0.05 mSv) in one hour at 30 centimeters from the source of radiation or from any surface that the radiation penetrates.

Subp. 145.

Radiation detector or detector.

"Radiation detector" or "detector" means a device that in the presence of radiation provides a signal or other indication suitable for use in measuring one or more quantities of incident radiation.

Subp. 146.

Radiation head.

"Radiation head" means the structure from which the useful beam emerges.

Subp. 147.

Radiation-producing equipment.

"Radiation-producing equipment" means any device capable of producing radiation.

Subp. 148.

Radiation protection.

"Radiation protection" means the use of time, distance, shielding, and other personnel protective garments.

Subp. 149.

Radiation safety officer.

"Radiation safety officer" means an individual who has the knowledge and training to apply appropriate radiation protection standards, and has been assigned such responsibility by the registrant.

Subp. 150.

Radiation therapy simulation system.

"Radiation therapy simulation system" means a radiographic, fluoroscopic, or CT x-ray system including all software applicable to the process intended for localizing the volume to be exposed during radiation therapy and confirming the position and size of the therapeutic irradiation field.

Subp. 151.

Radiograph.

"Radiograph" means an image produced on a radiosensitive surface, such as a photographic film or digital plate, by radiation other than visible light, such as by x-rays passed through an object or by photographing a fluoroscopic image that results in a permanent record.

Subp. 152.

Radiographic imaging system.

"Radiographic imaging system" means any system where a permanent or semipermanent image is recorded on an image receptor by the action of ionizing radiation.

Subp. 152a.

Radiology practitioner assistant or RPA.

"Radiology practitioner assistant" or "RPA" means an individual who is an advanced level radiographer registered with the American Registry of Radiologic Technologists and certified by the Certification Board for Radiology Practitioner Assistants. The individual is qualified by completion of an educational program recognized by the Board of Directors of the Certification Board for Radiology Practitioner Assistants. The RPA may provide patient services as specified in an agreement with a supervising radiologist.

Subp. 153.

Rated line voltage.

"Rated line voltage" means the range of potentials, in volts, of the supply line specified by the manufacturer at which the radiation-producing equipment is designed to operate.

Subp. 154.

Rating.

"Rating" means the operating limits as specified by the component manufacturer.

Subp. 155.

Recording.

"Recording" means producing a retrievable form of an image resulting from x-ray photons.

Subp. 156.

Reference man.

"Reference man" means a hypothetical aggregation of human physical and physiological characteristics. These characteristics may be used by researchers and public health workers to standardize results of experiments and to relate biological insult to a common base.

Subp. 157.

Reference plane.

"Reference plane" means a plane that is displaced from and parallel to the tomographic plane.

Subp. 159.

Registered radiologist assistant or RRA.

"Registered radiologist assistant" or "RRA" means a person who is an advanced level radiographer certified and registered in radiography by the American Registry of Radiologic Technologists and has successfully completed all elements of a radiologist assistant educational program recognized by the ARRT. The RRA would be able to provide patient services as specified in an agreement with a supervising radiologist.

Subp. 160.

Registrant.

"Registrant" means:

A.

a person having administrative control of any radiation-producing equipment except those specifically exempted under this chapter and who is legally obligated to register with the commissioner according to this chapter; or

Subp. 161.

Registration.

"Registration" means registration with the commissioner according to this chapter.

Subp. 162.

Rem.

"Rem" means a special unit of dose equivalence. The SI equivalent is 0.01 sievert.

Subp. 163.

Restricted area.

"Restricted area" means any area to which access or egress may be limited by the registrant for purposes of protection of individuals from exposure to radiation.

Subp. 164.

Retake or reject.

"Retake" or "reject" means any diagnostic radiographic imaging that had to be retaken, reexposing the patient to radiation because of some error, failure, or degradation in the radiographic imaging process.

Subp. 165.

Retake or reject analysis program.

"Retake or reject analysis program" means an ongoing analysis of retakes or rejects that provides information about existing imaging problems in a radiology department.

Subp. 166.

Roentgen or R.

"Roentgen" or "R" means a special unit of exposure. The roentgen is equal to 2.58 x 10-4 coulombs per kilogram of air.

Subp. 167.

Scattered radiation or secondary radiation.

"Scattered radiation" or "secondary radiation" means radiation that, during passage through matter, has been deviated in direction and may have also been modified by a decrease in energy.

Subp. 168.

Secondary dose-monitoring system.

"Secondary dose-monitoring system" means a system that will terminate irradiation if the primary dose-monitoring system fails.

Subp. 169.

Secondary protective barrier.

"Secondary protective barrier" means a barrier sufficient to attenuate stray radiation.

Subp. 170.

Sensitometer.

"Sensitometer" means an instrument designed to reproducibly expose a piece of film to a number of different levels of light intensity.

Subp. 171.

Sensitometric strip.

"Sensitometric strip" means a film exposed by a sensitometer, resulting in a gray scale range. The strips are used to measure the range of densities from minimum to maximum.

Subp. 172.

Sensitometry.

"Sensitometry" means a quantitative measurement of the response of film to exposure and development. Sensitometry is used to test the processor setup and stability.

Subp. 173.

Service provider.

"Service provider" means a person engaged in the business of assembling, installing, repairing, or replacing one or more components into diagnostic or industrial radiation-producing equipment system or subsystem or conducting equipment performance evaluations on diagnostic or industrial equipment. Service providers must be registered with the commissioner under part 4732.0275.

Subp. 174.

Shadow tray.

"Shadow tray" means a device attached to the radiation head to support auxiliary beam-limiting material.

Subp. 175.

Shutter.

"Shutter" means a device attached to the tube housing assembly that can totally intercept the useful beam and has a lead equivalency not less than that of the tube housing assembly.

Subp. 176.

SI equivalent.

"SI equivalent" means units that conform to the international system of units.

Subp. 177.

Sievert or Sv.

"Sievert" or "Sv" means the SI unit of any quantities expressed as dose equivalent. The conventional system equivalent is the rem.

Subp. 179.

Source of radiation.

"Source of radiation" means a device or equipment that emits or is capable of producing radiation. For purposes of this chapter, this is equivalent to radiation-producing equipment.

Subp. 180.

Source-to-image distance or SID.

"Source-to-image distance" or "SID" means the distance from the source to the center of the input surface of the image receptor.

Subp. 181.

Source-to-skin distance or SSD.

"Source-to-skin distance" or "SSD" means the distance between the source and the skin of the patient.

Subp. 182.

Spot check.

"Spot check" means a procedure that is performed to ensure that a previous calibration continues to be valid.

Subp. 183.

Spot film.

"Spot film" means a radiograph that is made during a fluoroscopic procedure to permanently record conditions that exist during that fluoroscopic procedure.

Subp. 184.

Spot-film device.

"Spot-film device" means a device intended to transport and position a radiographic image receptor between the x-ray source and fluoroscopic image receptor. Spot-film device includes a device intended to hold a cassette over the input end of the fluoroscopic image receptor to produce a radiograph.

Subp. 185.

Stationary beam therapy.

"Stationary beam therapy" means radiation therapy without relative displacement of the useful beam and the patient during irradiation.

Subp. 186.

Step wedge.

"Step wedge" means a quality control test tool made of type 1100 aluminum with 11 steps.

Subp. 187.

Stepless adjustment.

"Stepless adjustment" means a method of adjusting collimator blades continuously rather than in fixed increments.

Subp. 188.

Stochastic effects.

"Stochastic effects" means health effects that occur randomly and for which the probability of the effect occurring, rather than its severity, is assumed to be a linear function of dose without threshold. Hereditary effects and cancer incidence are examples of stochastic effects.

Subp. 189.

Storage.

"Storage" means a condition in which a device or radiation-producing equipment is not being used for an extended period of time and has been made inoperable.

Subp. 190.

Storage area.

"Storage area" means a location, facility, or vehicle that is locked or has a physical barrier to prevent accidental exposure to, tampering with, or unauthorized removal of the device, container, or source.

Subp. 191.

Stray radiation.

"Stray radiation" means the sum of leakage radiation and scattered radiation.

Subp. 192.

Supervising physician.

"Supervising physician" means a Minnesota licensed physician who accepts full medical responsibility for the performance, practice, and activities of a registered radiologist assistant or a radiology practitioner assistant.

Subp. 193.

Survey or radiation survey.

"Survey" or "radiation survey" means an evaluation of the radiological conditions and potential hazards incident to the use of radiation-producing equipment. When appropriate, such evaluation includes, but is not limited to, tests, physical examinations, and measurements of levels of radiation.

Subp. 194.

Target.

"Target" means the part of an x-ray tube or accelerator onto which a beam of accelerated particles is directed to produce ionizing radiation or other particles.

Subp. 195.

Technique factors.

"Technique factors" means the conditions of operation, specified as follows:

A.

for capacitor energy storage equipment, peak tube potential in kV and quantity of charge in mAs;

B.

for field emission equipment rated for pulsed operation, peak tube potential in kV, and number of x-ray pulses;

C.

for CT x-ray systems designed for pulsed operation, peak tube potential in kV, scan time in seconds, and either tube current in mA, x-ray pulse width in seconds, and the number of x-ray pulses per scan, or the product of milliamperage, x-ray pulse width, and the number of x-ray pulses in mAs;

D.

for CT x-ray systems not designed for pulsed operation, peak tube potential in kV, and either the tube current in mA and scan time in seconds, or the product of milliamperage and exposure time in mAs and the scan time when the scan time and exposure time are equivalent;

E.

for phototimed or automatic exposure controlled equipment, all necessary indicators including anatomical, if applicable, that must be activated before exposure; and

F.

for all other equipment, peak tube potential in kV and either tube current in mA and exposure time in seconds, or the product of milliamperage and exposure time in mAs.

Subp. 196.

Television receiver.

"Television receiver" means an electronic product designed to receive and display a television picture through broadcast, cable, or closed-circuit television.

Subp. 197.

Temporary job site.

"Temporary job site" means a location where radiography is performed, other than a location listed in a registration.

Subp. 198.

Termination of irradiation.

"Termination of irradiation" means the stopping of irradiation in a fashion that will not permit continuance of irradiation without the resetting of operating conditions at the control panel.

Subp. 199.

Therapeutic radiation machine.

"Therapeutic radiation machine" means x-ray or electron-producing equipment designed and used for external beam radiation therapy.

Subp. 200.

Therapeutic radiological physicist.

"Therapeutic radiological physicist" means an individual qualified to practice independently in the subfields for medical therapeutic physics who:

A.

is certified in radiological physics or therapeutic radiological physics by the American Board of Radiology;

C.

is certified in therapeutic radiological physics by the Canadian College of Medical Physics; or

D.

holds a masters degree or doctor's degree in medical physics, radiological sciences, or an equivalent field involving graduate study in physics applied to the application of radiation to humans from an accredited college or university and have at least one year of full-time practical training and experience involving work in a radiation therapy facility under an individual who meets the qualifications in this item or item A, B, or C.

Subp. 201.

Therapeutic-type protective tube housing.

"Therapeutic-type protective tube housing" means the definitions in items A to C.

A.

For x-ray therapy equipment not capable of operating at 500 kilovolt peak (kVp) or above, the following definition applies: an x-ray tube housing so constructed that the leakage radiation at a distance of one meter from the source does not exceed one rad (0.01 Gy) in an hour when the tube is operated at its maximum rated continuous current for the maximum rated tube potential.

B.

For x-ray therapy equipment capable of operation at 500 kilovolt peak (kVp) or above, the following definition applies: an x-ray tube housing so constructed that leakage radiation at a distance of one meter from the source does not exceed either one rad (0.01 Gy) in an hour or 0.1 percent of the useful beam dose rate at one meter from the source, whichever is greater, when the machine is operated at its maximum rated continuous current for the maximum rated accelerating potential.

C.

In either case, small areas of reduced protection are acceptable provided the average reading over any 100 square centimeters area at one meter distance from the source does not exceed the values given in items A and B.

Subp. 203.

Tomographic plane.

"Tomographic plane" means the geometric plane that is identified as corresponding to the output tomogram.

Subp. 204.

Tomographic section.

"Tomographic section" means the volume of an object whose x-ray attenuation properties are imaged in a tomogram.

Subp. 205.

Traceable to a standard.

"Traceable to a standard" means a comparison, either directly or indirectly, to a standard maintained by the National Institute of Standards and Technology (NIST) and that all comparisons have been documented.

Subp. 206.

Tube housing assembly.

"Tube housing assembly" means the tube housing with tube installed. It includes high voltage and filament transformers and other appropriate elements when contained within the tube housing.

Subp. 207.

Tube rating chart.

"Tube rating chart" means the set of curves that specify the rated limits of operation of the tube in terms of the technique factors.

Subp. 208.

Type 1100 aluminum alloy.

"Type 1100 aluminum alloy" means an alloy of aluminum that has a nominal chemical composition of 99 percent minimum aluminum and 0.12 percent copper.

Subp. 209.

Useful beam.

"Useful beam" means the radiation emanating from the tube housing port or the radiation head and passing through the aperture of the beam-limiting device when the exposure controls are in a mode to cause the system to produce radiation.

Subp. 210.

Utilization log.

"Utilization log" means a record of procedures conducted in a certain time frame and following a set of requirements:

Subp. 211.

Variable-aperture beam-limiting device.

"Variable-aperture beam-limiting device" means a beam-limiting device that has a capacity for stepless adjustment of the x-ray field size at a given SID.

Subp. 212.

Very high radiation area.

"Very high radiation area" means an area accessible to individuals, where radiation levels from radiation-producing equipment external to the body could result in an individual receiving an absorbed dose in excess of 500 rad (5 Gy) in one hour at one meter from any surface that the radiation penetrates.

Subp. 213.

Virtual source.

"Virtual source" means a point from which radiation appears to originate.

Subp. 214.

Visible area.

"Visible area" means the portion of the input surface of the image receptor over which incident x-ray photons are producing a visible image.

Subp. 215.

Wedge filter.

"Wedge filter" means an added filter effecting continuous change in transmission on all or part of the useful beam.

Subp. 216.

Worker.

"Worker" means an individual who engages in activities with sources of ionizing radiation that require registration by the commissioner and that are controlled by a registrant.

Subp. 217.

Written directive or written order.

"Written directive" or "written order" means a dated order either in writing or electronically for a specific patient, specific procedure, and has an indication of the licensed practitioner of the healing arts ordering the procedure.

Subp. 218.

X-ray control.

"X-ray control" means a device, switch, or other similar means by which an operator initiates and terminates the radiation exposure. The x-ray exposure control may include associated equipment such as timers and back-up timers.

Subp. 219.

X-ray equipment.

"X-ray equipment" means an x-ray system, subsystem, or component. Types of x-ray equipment are listed in items A to D.

B.

"Portable industrial x-ray equipment" means industrial x-ray equipment designed to be brought to a temporary job site to perform temporary industrial radiography.

C.

"Portable x-ray equipment" means x-ray equipment on wheels or casters and designed to be brought to a patient when the patient's condition does not permit transfer to a fixed location.

D.

"Stationary x-ray equipment" means x-ray equipment installed in a fixed location within a facility.

Subp. 220.

X-ray field.

"X-ray field" means the area of the intersection of the useful beam and any one of the set of planes parallel to and including the plane of the image receptor, whose perimeter is the locus of points at which the exposure rate is one-fourth of the maximum in the intersection.

Subp. 221.

X-ray generator.

"X-ray generator" means a type of electron accelerator in which the electron beam is used mainly for the production of x-rays.

Subp. 222.

X-ray high-voltage generator.

"X-ray high-voltage generator" means a device that transforms electrical energy from the potential supplied by the x-ray control to the tube operating potential. The device may also include means for transforming alternating current to direct current filament transformers for the x-ray tube, high-voltage switches, electrical protective devices, and other appropriate elements.

Subp. 223.

X-ray system.

"X-ray system" means an assemblage of components for the controlled production of x-rays. It includes minimally an x-ray high-voltage generator, an x-ray control, a tube housing assembly, a beam-limiting device, and the necessary supporting structures. Additional components that function with the system are considered integral parts of the system.

Subp. 224.

X-ray tube or tube.

"X-ray tube" or "tube" means an electron tube designed to be used primarily for the production of x-rays.

Statutory Authority:

MS s 144.12

History:

32 SR 777; L 2016 c 119 s 7

Published Electronically:

October 13, 2021

REGISTRATION REQUIREMENTS

4732.0200 REGISTRATION REQUIREMENTS FOR RADIATION-PRODUCING EQUIPMENT AND OTHER ELECTRONIC DEVICES THAT PRODUCE RADIATION.

Subpart 1.

Applicability.

For any facility, except those specifically exempted under this part or part 4732.0300, the person having administrative control of any ionizing radiation-producing equipment must be responsible for completing the registration form and submitting the applicable fee according to Minnesota Statutes, section 144.121. It is the registrant's obligation to keep the information for registration current. Should a change of control result in a change to the registrant's program, the registrant must notify the commissioner of that change according to this part. Persons with administrative control of the radiation-producing equipment must be responsible for maintaining equipment in compliance with a nationally recognized standard, such as Code of Federal Regulations, title 21, section 1020.30, the manufacturer's specifications, or parts 4732.1100 to 4732.1130.

Subp. 2.

New facility.

For a new facility, an application for registration must be submitted to the commissioner and approved prior to the operation of the equipment. Application for registration must be completed on forms furnished by the commissioner or an acceptable alternative and must be complete and accurate. The application must include the appropriate fee established in Minnesota Statutes, section 144.121, subdivision 1a.

B.

The registrant should notify the commissioner within 30 days of the following changes:

(4)

any change in the facility that might impact radiation exposures such as remodeling involving removal of shielded walls or barriers;

(6)

radiation safety officer or other personnel identified on the registration as having responsibility for radiation safety within the facility.

C.

A person shall not refer in any advertisement, to the fact that the ionizing radiation-producing equipment is registered with the commissioner, and shall not state or imply that the commissioner has approved any activity under such registration.

Subp. 3.

Issuance of notice of registration.

A.

Upon receipt of registration, the commissioner shall issue a notice of registration. Each notice of registration shall expire at the end of the indicated month and year.

B.

The commissioner may incorporate in the registration at the time of issuance or thereafter any additional requirements with respect to the registrant's receipt, possession, use, and transfer of radiation-producing equipment as the commissioner deems appropriate or necessary.

Subp. 4.

Renewal of registration.

A.

Renewal of registration must be submitted according to this subpart. Each registrant must renew following the schedule in subpart 5 as long as the activity requiring registration continues.

B.

The registrant must certify by signature or electronic signature that the information is accurate and complete.

C.

If there has been any additional radiation-producing equipment or other substantial change made after the existing registration or renewal, the registrant must include all pertinent information regarding the addition or change.

Subp. 5.

Staggered schedule for renewal of registration.

Each registration under this chapter must be renewed on or before the first day of the calendar quarter specified in items A to D. The following schedule is based on the registrant's business address within the state:

A.

Beginning January 1, 2008: Hennepin County registrants including the University of Minnesota, Minneapolis campus;

C.

Beginning July 1, 2008: Aitkin, Benton, Carlton, Cass, Chisago, Cook, Crow Wing, Isanti, Itasca, Kanabec, Koochiching, Lake Mille Lacs, Morrison, Pine, St. Louis, Becker, Beltrami, Big Stone, Chippewa, Clay, Clearwater, Douglas, Grant, Hubbard, Kittson, Lac Qui Parle, Lake of the Woods, Mahnomen, Marshall, Norman, Otter Tail, Pennington, Polk, Pope, Red Lake, Roseau, Stearns, Stevens, Swift, Todd, Traverse, Wadena, and Wilkin County registrants, and registrants whose business addresses are outside the state; and

D.

Beginning October 1, 2007: Brown, Carver, Cottonwood, Faribault, Jackson, Kandiyohi, Lincoln, Lyon, Martin, McLeod, Meeker, Murray, Nicollet, Nobles, Pipestone, Redwood, Renville, Rock, Sherburne, Sibley, Watonwan, Wright, Yellow Medicine, Blue Earth, Dodge, Fillmore, Freeborn, Goodhue, Houston, Le Sueur, Mower, Olmsted, Rice, Scott, Steele, Wabasha, Waseca, and Winona County registrants.

Subp. 6.

Renewals affected by change of location.

A registrant whose business address changes from one county to another must renew the registration with the county of relocation according to the schedule in subpart 5. The registrant shall not be assessed penalty fees for not renewing with the county of previous location.

Subp. 7.

Change of ownership.

In addition to the notification required in subpart 1, the registration of the facility is not transferable as part of a change in ownership.

Statutory Authority:

MS s 144.12

History:

32 SR 777

Published Electronically:

December 10, 2007

4732.0210 REGISTRATION FEES.

The initial registration application or renewal for registration of radiation-producing equipment required under part 4732.0200 must be accompanied by the fee established in Minnesota Statutes, section 144.121, subdivision 1a. The registration fee is nonrefundable.

Statutory Authority:

MS s 144.12

History:

32 SR 777

Published Electronically:

December 10, 2007

4732.0220 GENERAL REQUIREMENTS FOR ALL FACILITIES.

Subpart 1.

Responsibilities of registrant.

The registrant must:

A.

ensure compliance with applicable parts of this chapter and in the operation of the equipment that are consistent with each registrant's area of use;

B.

notify the commissioner within 30 days of any change in the ownership, addition of, or disposition of registered radiation-producing equipment; and

Subp. 2.

Submissions.

A.

Any submission of any information provided to the commissioner by a registrant must be complete and accurate in all material submitted.

B.

All communications and reports concerning these regulations, applications, and violations filed thereunder, must be addressed to or delivered to the Minnesota Department of Health, Radiation Control Unit, 625 Robert Street North, P. O. Box 64975, St. Paul, Minnesota 55164-0975.

Subp. 3.

Shielding requirements.

All registrants must maintain documentation of the radiation shielding installed in their facility. The documentation must be:

B.

a shielding plan that was completed by a service provider or an appropriate radiological physicist;

D.

verified by a detailed radiation survey covering radiation levels at the operator position and at pertinent points outside the room during normal operation; and

E.

if the registrant cannot verify shielding compliance by items A to C, a detailed radiation survey covering the radiation levels at the operator position and at pertinent points outside the room during normal operation must be completed and the documentation maintained.

Subp. 4.

Exemption.

Dental facilities with only intraoral capabilities are exempted from the shielding requirements in subpart 3.

Statutory Authority:

MS s 144.12

History:

32 SR 777

Published Electronically:

December 10, 2007

4732.0250 RECIPROCITY FOR OUT-OF-STATE RADIATION-PRODUCING EQUIPMENT.

Subpart 1.

Applicability.

Whenever radiation-producing equipment is to be brought into the state for any temporary use, a written notice must be provided to the commissioner at least three working days before the equipment is to be used in the state. Upon request to the department, permission to process use of equipment sooner may be granted if the three-day notification period would impose an undue hardship on the person. The notice required in this subpart must include:

Subp. 3.

Inspections.

Inspections by the commissioner may be performed on any radiation-producing equipment being used in Minnesota on a reciprocal basis for compliance with this chapter.

Statutory Authority:

MS s 144.12

History:

32 SR 777

Published Electronically:

December 10, 2007

4732.0275 REGISTRATION OF SERVICE PROVIDERS.

Subpart 1.

Application for service provider registration.

A.

A person who is engaged in the business of assembling, installing, repairing, or replacing one or more components in a radiation-producing equipment system or conducting equipment performance evaluations on diagnostic or industrial radiation-producing equipment must apply for registration with the commissioner within 30 days following the effective date of this chapter or prior to furnishing or offering to furnish any services. The services may include, but are not limited to:

(1)

installing, replacing, or repairing radiation-producing equipment and associated components; and

(2)

performing equipment performance evaluations on diagnostic or industrial radiation-producing equipment and associated components.

B.

All applications for registration must be completed on forms furnished by the commissioner and must include all information specified by the commissioner.

C.

A person applying for registration under this part must specify:

(2)

the training and experience that qualify them to discharge the services for which they are applying for registration;

(3)

the type of measurement instruments to be used, frequency of calibration, and calibration facility; and

Subp. 2.

Issuance of notice of registration.

A.

Upon a determination that an applicant meets the requirements of this chapter, the commissioner shall issue a notice of registration. Each notice of registration expires at the end of the specified day in the month and year stated in the notice.

B.

The commissioner may incorporate in the notice of registration at the time of issuance or after by appropriate rule, or regulation, any additional requirements and conditions deemed appropriate or necessary by the commissioner.

Subp. 3.

Renewal of registration.

Renewal of the registration for service providers must be completed 30 days prior to the end of the month of the current registration.

Subp. 4.

Exemption.

An individual employed by a registrant to perform in-house calibrations, equipment performance evaluations, or repairs of diagnostic or industrial radiation-producing equipment is exempt from registering as a service provider. An in-house employee may not perform these tasks elsewhere unless registered as a service provider.

Statutory Authority:

MS s 144.12

History:

32 SR 777

Published Electronically:

December 10, 2007

4732.0280 SERVICE PROVIDER'S RESPONSIBILITY.

Subpart 1.

General requirements.

A person shall not make, sell, lease, transfer, lend, repair, or install radiation-producing equipment or the parts used in connection with this equipment unless the parts and equipment, when properly placed in operation, meet the federal requirements for the equipment manufacturer's specifications and the requirements of this chapter.

Subp. 2.

Notification requirements.

A registered service provider must meet the notification requirements in this subpart.

A.

A person selling, leasing, or transferring radiation-producing equipment must notify the commissioner in writing within 15 days of the sale, lease, or transfer, and must supply the name and address of the purchaser and other pertinent information required by the commissioner.

B.

Installation calibrations and equipment performance test reports must be sent to the facility within 30 days of the tests. The service provider must keep copies of these test reports for four years after completion.

C.

The test reports must include written recommendations for necessary corrections or improvements.

Subp. 3.

Calibration reports at time of installation.

At the time of installation, calibrations must be performed on diagnostic or industrial radiation-producing equipment prior to first use on patients according to nationally recognized standards, such as:

D.

the service provider's written report, which must include:

(4)

the numerical results of the tests including any appropriate films. If the result of the test is not a numerical answer, a pass or fail or "yes" or "no" answer is acceptable;

(5)

any written recommendations necessary for corrective actions to maintain compliance with this chapter; and

Subp. 4.

Equipment performance tests.

At the time of the equipment performance tests, the tests must be completed at intervals not to exceed 24 months. The tests must be performed over the clinical range on the equipment according to parts 4732.1100 to 4732.1130; Code of Federal Regulations, title 21, section 1020; or the manufacturer's specifications. The registered service provider must keep copies of these test reports for four years after completion. The service provider's written report to the facility must include:

D.

the numerical results of the tests including any appropriate films. If the result of the test is not a numerical answer, a pass or fail or "yes" or "no" answer is acceptable;

E.

any written recommendations necessary for corrective actions to maintain compliance with this chapter; and

Subp. 5.

Individual monitoring.

The vendor employing registered service providers must provide individual monitoring devices and reports for their occupational exposure according to part 4732.0440, where applicable.

Subp. 6.

Phantom use.